What are some of the materials that can be processed using a Coarse Powder Grinding Mill

A Coarse Powder Grinding Mill can process a wide range of materials, including but not limited to barite, quartz, feldspar, mica, calcite, talc, apatite, gypsum, fluorite, limestone, dolomite, diatomite, ceramic soil, clay, marble, granite, fly ash, kaolin, calcium carbonate, slag, bauxite, and glass. It is a versatile machine suitable for handling various materials.

How does a European Coarse Powder Grinding Mill operate

The European Coarse Powder Grinding Mill operates based on a simple principle. The main unit is driven by a motor and triangle belts, which, in turn, rotate the rollers. When large materials enter the crusher through the feed inlet, they are initially crushed by high-speed hammers. These crushed materials are then thrown to the support iron for further crushing. Qualified materials are screened out and exit from the gap of the grate bars, while unqualified materials remain in the crushing cavity to be further hammered and ground until they reach the standard size. The size of the final product can be adjusted by changing the grate bars, and the gap between the rotors and the grate bars can also be adjusted according to specific requirements. To prevent clogging of the crusher, the proportion of water in the crushing materials should not exceed 20%.

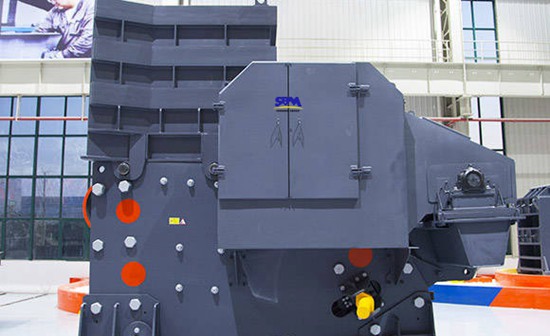

What is the basic structure of a European Coarse Powder Grinding Mill

A European Coarse Powder Grinding Mill consists of several key components. It mainly comprises a frame, rotor, support iron, and grate bars. The frame is divided into an upper part and a lower part, both made of welded steel plates. The frame also includes replaceable liners made of high manganese steel. The rotors consist of turn plates, pin shafts, and hammers that are grouped regularly on the main shaft.

What is the primary purpose of a Coarse Powder Grinding Mill

A Coarse Powder Grinding Mill is primarily designed for crushing various rocks and stones with a comprehensive strength not exceeding 320 MPa. Its main purpose is to process materials into coarse powder and small particles. It finds applications in various industries such as metallurgy, mining, chemical, cement, coal, sand-making, construction, refractory materials, and ceramics.

What is the significance of the high manganese steel liners in the Coarse Powder Grinding Mill

The high manganese steel liners in the Coarse Powder Grinding Mill serve an important purpose. They are positioned within the frame and can be replaced after wearing out. These liners provide protection to the internal components of the mill and help maintain the efficiency and durability of the machine. By replacing these liners when worn, the mill can continue to operate effectively and extend its lifespan, reducing maintenance costs.