ultrafine grinding mill

- What is the primary purpose of the Ultra fine Grinding Mill, and what is its target fineness range in terms of mesh size?

- What are the advantages of not having rolling bearings and screws inside the grinding chamber of the Ultrafine Grinding Mill, and how does this design improve machine reliability?

- How does the open circuit system with negative pressure contribute to the overall operation of the Ultrafine Grinding Mill?

- How does the pulse dust collector in the Ultrafine Grinding Mill contribute to eco-friendliness during its operation?

- Could you elaborate on the working principle of the Ultrafine Grinding Mill, especially the role of grinding rollers and airflow in the process?

- Can you explain the digitalized processing and its impact on the precision of the Ultrafine Grinding Mill's core parts?

- How does the Ultrafine Grinding Mill compare to other types of grinding mills in terms of energy efficiency and output capacity?

- What are the specific advantages of using the cage-type powder selector in the Ultrafine Grinding Mill?

- Are there any notable applications or industries where the Ultrafine Grinding Mill is particularly beneficial or widely used?

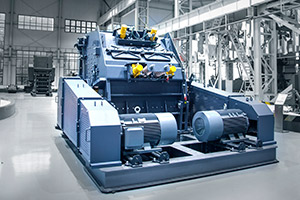

SCM Ultra fine Grinding Machine Co., Ltd has recently developed an innovative ultrafine powder grinding system tailored for various non-metallic ore grinding applications in cement plants.The heart of this system is the ultra fine grinding mill, also known as the superfine vertical mill. It incorporates essential components like the motor, reducer, roller, pressure device, machine body, hydraulic device, and gas separator, it operates within a closed air loop system.

Raw materials are introduced into the ultra fine powder grinder through an elevator or other equipment, and an airlock device is strategically placed at the feeding point. Once inside the ultra fine grinding mill, the material is carried to the upper powder separation section by hot air.Large particle powder is recirculated to the grinding disc for further refinement, while the qualified fine powder is conveyed to the cyclone dust collector via the air pipe. Subsequently, the fine powder is directed to the bag filter through the cyclone dust collector's discharge pipe and is ultimately discharged through the bag filter outlet. This system is capable of producing material particles within the range of 325 to 2500 mesh.This comprehensive system offers the advantages of a vertical mill system, including high grinding efficiency, a compact footprint, excellent sealing, energy efficiency, and environmental protection. Its user-friendly design facilitates ease of maintenance and repair, ultimately reducing investment costs and elevating production efficiency.

The Ultrafine Grinding Mill is a cutting-edge piece of equipment designed to produce superfine powder within a broad range of 325-2500 mesh. Its primary objective is to enable ultra fine grinding for a variety of materials, which is essential in industries like mining, construction, and materials processing. This enables the production of powders with extremely fine particle sizes, making it suitable for various applications where traditional grinding methods fall short. This adaptability is made possible by the German technology-based cage-type powder selector, which enhances the precision of powder separation. Users can configure a multi-head cage-type powder selector to meet specific requirements related to yield, fineness, and sieving rate. As a result, the product fineness can be easily adjusted within the specified range, and the screening rate can achieve d97≤5μm in a single pass.

The absence of rolling bearings and screws inside the grinding chamber of the Ultra fine Grinding Mill has significant advantages. It eliminates concerns about potential damage to bearings and their sealing parts, as well as any machine damage issues caused by loose screws. This design feature enhances the reliability and longevity of the equipment, reducing the need for frequent maintenance. The lubricating device is also situated outside the main shaft, enabling lubrication without shutdown, facilitating continuous 24-hour production.

The open circuit system with negative pressure in the Ultra fine Grinding Mill contributes to its efficient operation. This design allows for continuous production without the need for frequent shutdowns, resulting in higher productivity and operational flexibility. Additionally, it aligns with national environmental protection standards, ensuring that the operation complies with environmental regulations. The presence of impulse dust removal and filtering measures further enhances the overall environmental performance of the system.

The Ultra fine Grinding Mill's eco-friendliness is a notable feature, primarily due to the efficient pulse dust collector integrated into the system. This collector ensures that no dust pollution occurs during the operation of the entire milling system, maintaining a clean and environmentally responsible workspace. Additionally, silencers and noise elimination rooms are configured to reduce noise levels, aligning with national environmental protection standards.

The working principle of the Ultra fine Grinding Mill is centered around grinding rollers and rings. When the mill is in operation, dozens of grinding rollers start to rotate and roll. Under the influence of centrifugal force, materials on the dispersing plate are thrown to the rim and drop into the grinding chamber. Within the circuit, materials undergo compression and grinding. After multiple grinding cycles, materials are carried into the powder selector by the airflow. The impeller of the powder selector further refines the materials, with those failing to meet the desired fineness being sent back to the grinding chamber for further processing. Qualified powders are collected by a cyclone powder collector and discharged as finished products from the bottom. Any remaining powders are collected by an impulse dust remover and may adhere to the surface of the filler-bag. To address this, high-pressure airflow, controlled by the impulse valve, is used to inflate and vigorously shake the filler-bag. This sudden shake helps dislodge the remaining materials and collect them as finished products. Following this, the airflow undergoes filtering and is discharged into the atmosphere. The system operates as an open circuit under negative pressure.

The Ultra fine Grinding Mill leverages digitalized processing with advanced manufacturing technologies. This includes the use of numerical control machine tools for operations like cutting steel plates, bending, planing, milling, and paint spraying. These processes are controlled numerically, resulting in high machining precision, particularly for the core components of the equipment. This commitment to precision manufacturing ensures the highest quality and consistency in the end product.

It boasts newly designed grinding curves that improve the efficiency of grinding rollers and rings, which stands out compared to other types of grinding mills due to its superior energy efficiency and output capacity. When compared to traditional grinding mills like jet grinding mills and ball grinding mills, the Ultra fine Grinding Mill's production capacity is 40% higher, and its yield is double that of ball grinding mills, all while consuming only 30% of the energy. This combination of high output and low energy consumption makes it a compelling choice for industries seeking efficient grinding solutions.

The cage-type powder selector in the Ultra fine Grinding Mill, utilizing German technologies, plays a crucial role in enhancing its performance. It effectively increases the precision of powder separation, ensuring that the desired fineness is achieved consistently. Moreover, users can configure a multi-head cage-type powder selector to tailor the equipment to their specific needs in terms of yield, fineness, and sieving rate. This flexibility is a significant advantage when dealing with different materials and production requirements.

The Ultra fine Grinding Mill finds applications in various industries that require the production of ultrafine powders. These industries include mining, construction, and materials processing, where materials like limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, and coal powder need to be finely ground for specific purposes. Its ability to process a wide range of materials and offer adjustable fineness levels makes it a versatile solution for industries with diverse material processing requirements. Additionally, its eco-friendly features, such as dust removal and noise reduction, make it a responsible choice for environmentally conscious industries.