What are some of the key features and advantages of the HGM ultrafine grinding mill for coconut shell powder making

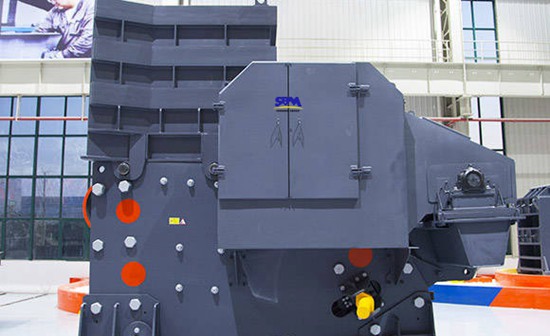

The HGM ultrafine grinding mill offers several key features and advantages, including stable operation, high efficiency, energy-saving, safety and environmental protection, a small footprint, minimal investment, intelligent control, convenient maintenance, long service life, factory direct sales, and guaranteed after-sales service. Additionally, it can be equipped with a high-efficiency pulse dust collector to prevent dust pollution and reduce noise during operation. There are no rolling bearings and screws inside the mill, eliminating concerns about bearing or seal damage and loose screws. The lubrication device is designed for external non-stop lubrication, allowing continuous 24-hour production.

How does the machine ensure environmental protection during its operation

The HGM ultrafine grinding mill for coconut shell powder making incorporates features for environmental protection. It is equipped with a high-efficiency pulse dust collector, which prevents dust pollution during operation. The machine also comes with a muffler and an anechoic room to reduce noise levels, aligning its production with international environmental protection standards.

Describe the working principle of the coconut shell powder making machine when it's in operation.

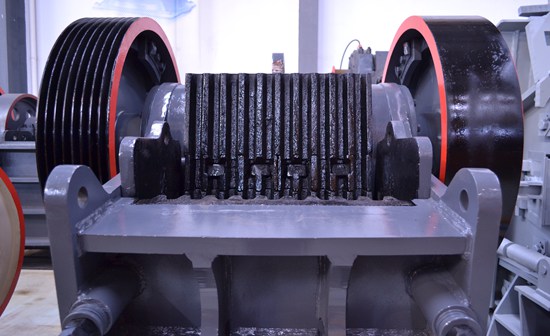

When the coconut shell powder making machine is in operation, the grinding roller rolls in the annular groove, pushing the coconut shell to the edge of the turntable due to centrifugal force. The coconut shell then falls into the grinding chamber, where it is repeatedly squeezed, crushed, and ground by the drum. The material is divided into multiple layers and continuously crushed and ground into fine powder.

How can the fineness of the coconut shell powder be adjusted, and what is the one-time screening rate achievable with this machine

The fineness of the coconut shell powder can be adjusted arbitrarily between 150-3000 mesh using the HGM ultrafine grinding mill. The one-time screening rate can reach d97≤5μm, ensuring the production of finely ground coconut shell powder.

What is the main machine used to grind coconut shells into a fine powder, and what is its adjustable fineness range

The main machine used to grind coconut shells into a fine powder is the HGM ultrafine grinding mill. It can adjust the fineness of the coconut shell powder freely within the range of 150-3000 mesh according to the specific requirements.

What are some of the potential applications of coconut shell powder produced by this machine

The coconut shell powder obtained from this machine has various applications, including as a covering, garden bed base, organic fertilizer, edible fungus substrate, and biomass power generation material. It can also be used to manufacture high-density boards, particleboard, and paper. Additionally, 100-mesh coconut shell powder can serve as the primary raw material for mosquito coils, and it can be used as glass coconut shell anti-mold powder, contributing to preventing mold and scratches on glass surfaces.

What are some of the materials that can be processed using the coconut husk powder making machine, aside from coconut shells

The coconut husk powder making machine can process a variety of materials, including non-metallic ores such as limestone, talc, marble, dolomite, and barite. It can also handle eggshells, shells, bamboo, and other similar materials.