What are the key features and advantages of the HGM superfine powder grinding mill

The HGM superfine powder grinding mill is a critical component in the production of sepiolite powder. It offers several key features and advantages:

- Improved Grinding Efficiency: The design of the grinding roller, grinding ring, and grinding curve enhances the mill's efficiency. It provides a 40% higher production capacity compared to jet mills and stirring mills, with only 30% of the energy consumption.

- Flexible Fineness Control: Equipped with a multi-head cage-type powder concentrator, the mill allows for arbitrary fineness adjustment between 150-3000 mesh, with a one-time screening rate as low as d97≤5μm.

- Low Dust Pollution: The mill includes a high-efficiency pulse dust collector, ensuring minimal dust pollution during operation. Silencers and anechoic rooms are added to reduce noise.

- Energy Efficiency: With a PLC control system and multi-head powder selection technology, the mill can precisely control parameters like grinding pressure and speed, resulting in a 30%-50% reduction in energy consumption compared to ordinary mills.

- Mechanical Protection: Electronic and mechanical limit protection technologies prevent destructive impacts caused by machine vibration, ensuring operational stability.

- Maintenance-Friendly: The reversible structure and hydraulic adjustment system allow for easy and quick maintenance, reducing downtime losses.

What are the functions of the electromagnetic vibrating feeder and bucket elevator in sepiolite powder production

The electromagnetic vibrating feeder and bucket elevator play crucial roles in the sepiolite powder production process:

- Electromagnetic Vibrating Feeder: This device ensures the even and continuous feeding of sepiolite into the processing equipment. It is known for its small size, lightweight design, convenient maintenance, low operating costs, and minimal wear of the feeding trough, making it an efficient feeding solution.

- Bucket Elevator: The bucket elevator is responsible for vertically transporting sepiolite to the necessary equipment for subsequent processing. It offers reliable operation, a high conveying capacity, low maintenance requirements, and minimal wear on its components, contributing to efficient material handling.

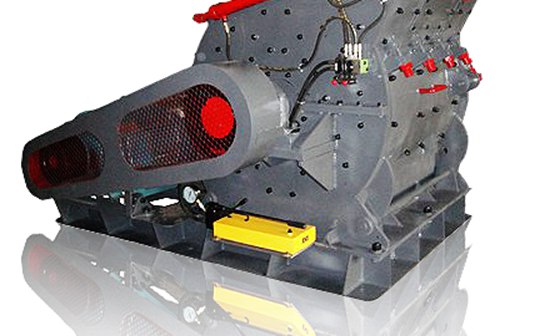

What are the key features and advantages of the coarse powder grinding mill for sepiolite

The coarse powder grinding mill serves as a crucial element in the production of sepiolite powder, offering specific features and advantages:

- High Capacity: This mill is capable of crushing various rocks and stones with a comprehensive strength not exceeding 320 MPa into coarse powder and small particles.

- Low Power Consumption: It provides a balance between high capacity and low power consumption, making it an efficient choice.

- Uniform Particle Size: The mill produces coarse powder with a uniform particle size and high crushing ratio.

- Simple Structure: With its uncomplicated design, it offers easy operation and maintenance.

- Cost-Effective: The coarse powder grinding mill is cost-effective and requires low investment.

What are the characteristics and benefits of the CLUM series vertical mill for sepiolite powder grinding

The CLUM series vertical mill is another key component for grinding sepiolite powder. It comes with distinct characteristics and benefits:

- Ultrafine Powder Production: The mill can produce ultrafine powders with a fineness down to 2 microns, with 90% content for a single milling process.

- High Output and Efficiency: It offers a high capacity and low power consumption, promoting efficient and environmentally friendly production.

- Stable Operation: The vertical-shaped star wheel reducer ensures higher transmission efficiency and smoother operation, while the low consumption of grinding media and low finished product temperatures contribute to stable production.

- Compact Design: Its compact structure and suitable height make it easy to operate and maintain, with optional automatic control features.

What is sepiolite powder, and how is it produced

Sepiolite powder is a finely ground form of sepiolite, which is a natural, non-toxic, tasteless, non-asbestos, and non-radioactive clay mineral. It has the highest specific surface area among non-metallic minerals, providing it with exceptional adsorption capacity.

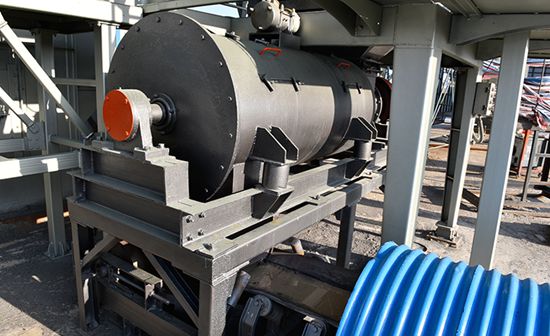

The production process of sepiolite powder typically involves several steps:

- Raw Material Crushing: Raw sepiolite is first fed into a jaw crusher for primary crushing to achieve the required particle size.

- Particle Storage: Crushed sepiolite particles meeting size requirements are stored in a storage bin using a bucket elevator.

- Grinding Operation: Electromagnetic vibrating feeders evenly feed the stored material into a superfine powder grinding mill, where it is pulverized into fine powder.

- Classification: The pulverized sepiolite is then sorted by a classifier under the influence of a blower. Particles not meeting the required fineness are recycled for further grinding, while those meeting the criteria are collected in a powder collection bin for packaging.

The equipment involved in the sepiolite powder production process includes jaw crushers, bucket elevators, storage bins, vibrating feeders, ore mills, powder classifiers, powder collectors, pulse dust collectors, high-pressure fans, and electrical control systems. The finely ground powder meeting the desired specifications is the final product.

What are the fineness requirements for sepiolite powder in various applications, and how is it achieved

Sepiolite powder is used in a wide range of applications, each with specific fineness requirements. Common fineness levels include 100 mesh, 200 mesh, 325 mesh, 600 mesh, 800 mesh, and 1250 mesh, among others. Achieving the desired fineness is essential for the success of these applications.

For sepiolite powder production, the choice of grinding mill machine is crucial to meet these diverse fineness requirements. Different grinding mills can be configured to achieve optimal results. The newly designed grinding roller, grinding ring, and grinding curve in the HGM superfine powder grinding mill enhance grinding efficiency and allow the product to be finely ground within the desired mesh range.

On the other hand, the CLUM series vertical mill is highly effective for producing ultrafine powders down to 2 microns with a content of 90% for a single milling process. This makes it suitable for applications with the most stringent fineness requirements.

By choosing the appropriate grinding mill machine, sepiolite powder can be tailored to meet the fineness requirements of various industries and applications effectively.

What is sepiolite, and what are its properties and uses

Sepiolite is a fibrous hydrous magnesium silicate mineral that is known for its unique properties. It is typically white, light gray, light yellow, or other colors, and it has a smooth and sticky texture with a hardness ranging from 2 to 3 on the Mohs scale. Sepiolite possesses several valuable properties, such as low shrinkage, good plasticity, a large specific surface area, strong adsorption capabilities, solubility in hydrochloric acid, lightweight nature, and resistance to factors like heat, insulation, corrosion, radiation, and thermal stability.

Due to its exceptional qualities, sepiolite finds numerous applications across various industries. It is widely used in medicine, ceramics, plastics, coatings, rubber, agriculture, chemical industry, construction, and more. Sepiolite is recognized for its adsorption, rheological, and catalytic properties, making it one of the most versatile and widely used mineral raw materials in the world.