What are the therapeutic applications of calcite in traditional Chinese medicine

In traditional Chinese medicine, calcite is used for various therapeutic purposes:

- It can treat osteoporosis and prevent arteriosclerosis.

- Calcite is believed to help with memory loss.

- It is used to eliminate odors and moisture.

- Calcite can reduce capillary permeability and inhibit fluid extravasation and edema.

- It is also thought to have a calming effect on nerve stress.

What are the key stages in the production process of calcite powder

The production of calcite powder involves several key stages:

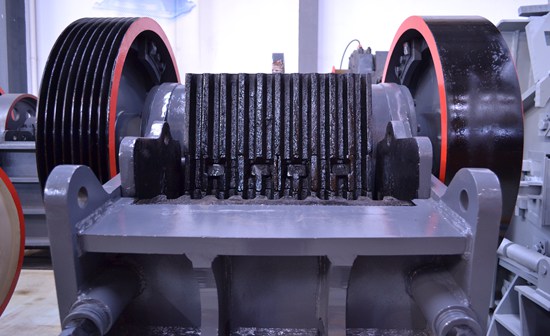

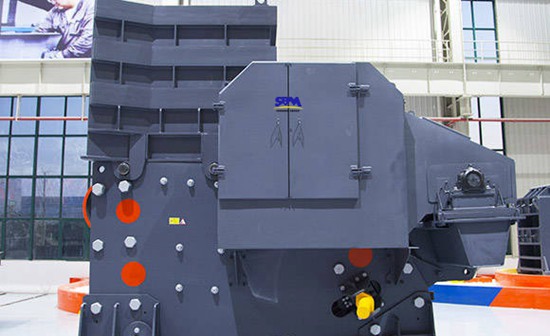

- Crushing Stage: Large pieces of calcite are initially crushed by a crusher, equipped with a processing dust removal machine, and then further crushed by an impact crusher or cone crusher.

- Screening Stage: The crushed calcite is screened to obtain various sizes and specifications of calcite.

- Grinding Stage: The calcite is ground into powder using an industrial ultrafine powder grinder.

- Classification Stage: The ground calcite powder is classified, and any unqualified powder is returned for re-grinding.

- Powder Collection Stage: The final calcite powder is collected and separated from the gas, then sent to storage or packing.

What is the primary use of calcite in various industries

Calcite is utilized in various industries for different purposes. In the construction industry, it is used to produce cement and lime. Additionally, it is employed in making high-quality putty powder, plastic, paper, and even toothpaste. Calcite is used as a filling additive in the food industry, and in glass production, adding calcite can make glass translucent, making it suitable for creating glass lampshades. Furthermore, calcite is used in the metallurgical industry as a flux, and it is still a common component in traditional Chinese medicine with various therapeutic applications.

What are the characteristics of calcite, and how does its color vary

Calcite is a calcium carbonate mineral with a wide distribution and diverse characteristics. Its crystal shapes vary and can include clusters of crystals, granular, massive, fibrous, stalactite, and earthy forms. The color of calcite can vary depending on the impurities it contains. For instance, when iron and manganese are present, it can appear as light yellow, light red, brown-black, and more. However, in its pure form, calcite is typically white or colorless.

How is calcite utilized in the rubber, plastic, paint, and paper industries

Calcite has various applications in different industries:

- Rubber Industry: Filling rubber with calcium carbonate can increase the volume of rubber products and enhance tensile strength, tear strength, crack resistance, and abrasion resistance.

- Plastic Industry: In the plastic industry, heavy calcium powder is used for masterbatch and color masterbatch, improving dimensional stability and maintaining whiteness even at high temperatures.

- Paint Industry: Heavy calcium powder is employed in the paint industry, contributing to latex paint quality and whiteness.

- Paper Industry: In the paper industry, calcite plays a crucial role in ensuring paper strength, whiteness, and cost-effectiveness.

What are some key statistics about the company mentioned in the text regarding its products and presence

The company mentioned in the text has several notable statistics:

- Exported products to more than 170 countries and regions worldwide.

- Operates more than 30 overseas branches and business organizations.

- Ranked as the top company in China's mining machinery industry for ten consecutive years.

What are the advantages of using HGM and CLUM ultrafine grinding mills for processing calcite

HGM and CLUM ultrafine grinding mills offer several advantages for processing calcite:

- Small footprint and simple operation.

- Convenient maintenance and high grinding efficiency.

- Environmental protection and low investment.

- High output and better powder shape, especially in CLUM.

- Long service life and certain drying functionality.

What are the primary industrial applications of calcite powder with different fineness levels

Calcite powder is used in various industries with different fineness levels. Common calcite powder has a range of fineness, including 3000 mesh, 2500 mesh, 2000 mesh, 1000 mesh, 1500 mesh, 1250 mesh, 800 mesh, and more. These fineness levels are applicable to different fields. For instance, 300-3000 mesh calcite powder is used in ultrafine applications. If a finer calcite powder below 300 mesh is required, YGM Raymond mill can be used to grind 80-600 mesh calcite powder.