Can you explain the working principle of the glass powder making machine

The glass powder making machine works by first crushing large materials with a hammer crusher. These crushed materials are then sent to a silo, where they are fed into the main machine continuously. The materials fall onto a bulk material tray on the upper part of the main machine's turntable. Inside the main machine, dozens of grinding rollers rotate and roll in a ring. Under the influence of centrifugal force, the material is scattered to the periphery by the bulk disc and falls into the grinding cavity. There, it is stamped, rolled, and ground by the grinding roller.

After multiple layers of crushing and grinding, the material enters a powder classifier with the airflow generated by a fan for classification. If the material does not meet the desired fineness, it returns to the grinding cavity for re-milling. The material that meets the fineness requirements enters a cyclone powder collector with the airflow, where part of the powder is separated and collected and then discharged from the bottom. The remaining powder enters a pulse dust collector, adheres to the filter bag, and is periodically removed by high-pressure airflow, allowing for continuous production.

What is the typical production line for a glass powder making machine

A typical production line for a glass powder making machine includes several components:

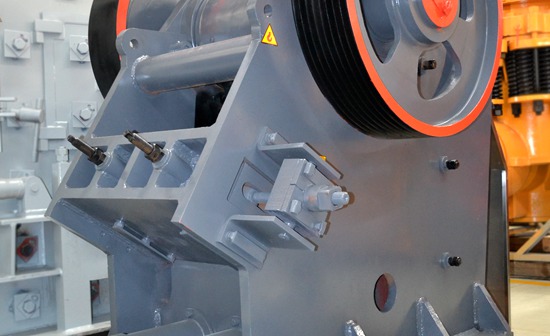

- Crushers

- Conveyor belts

- Vibrating screens

- Elevators

- Storage bins

- Grinding mills

- Classifiers

- Powder collectors

- Balers

- Dust collectors

- Silencers

- Motors

This production line processes broken glass into glass powder, which can be used in various applications, such as construction, paint production, and more.

What are the key features of the glass powder making machine

The glass powder making machine offers several key features, including adjustable fineness ranging from 150-3000 mesh, an output capacity of 0.5-45t/h, and the ability to process various materials such as non-metallic ores, shells, bamboo, coconut shells, and glass. It boasts a small footprint, stable operation, intelligent control, convenient maintenance, long service life of wearing parts, safety, and environmental protection, as well as flexible fineness adjustment.

What are the characteristics and uses of glass powder

Glass powder is an inorganic amorphous ultrafine particle powder with characteristics including good transparency, high hardness, uniform particle size distribution, and excellent dispersibility and compatibility with other components in resin and paint systems. It is used in various applications, including:

- Combination of pavement, building bricks, glass wool insulation materials, and honeycomb structure materials.

- Improving the basic chemical properties of cement in construction.

- Making reflector materials and clothing decorations.

- Producing high-end furniture topcoats with properties like yellowing resistance and high-temperature resistance.

- Applications in the railway, construction, aerospace, advertising, and display industries.

- Molding into synthetic slate products when mixed with plastic waste.

- Usage in sewage pipe production.

Glass powder finds diverse applications due to its unique properties and versatility.

What are the advantages of using a glass powder making machine

The advantages of the glass powder making machine include:

- Higher output and lower energy consumption compared to other grinding mills.

- Adjustable fineness between 150-3000 mesh, offering flexibility to meet specific requirements.

- No rolling bearings and screws in the grinding chamber, reducing the risk of machine damage.

- Pulse dust collector for environmentally friendly operation, with no dust pollution and reduced noise.