What are some of the diverse applications of fluorite in various industries

Fluorite has a wide range of applications in different industries, including:

- Aluminum Production: It is used to produce hydrofluoric acid and aluminum fluoride for the aluminum smelting industry.

- Chemical Industry: Fluorite is a crucial raw material for producing various fluorine compounds used in refrigerants, solvents, and more.

- Medicine: It is used to create fluorine-containing drugs, artificial blood, and other medical products.

- Building Materials: In the cement, glass, ceramic, and construction industries, fluorite acts as a flux and color enhancer.

- Enamel Production: It is used to improve the color and properties of enamel in the ceramic and enamel industries.

What are the key steps in the processing of fluorite ore to obtain fluorite powder

The processing of fluorite ore to obtain fluorite powder involves several key steps:

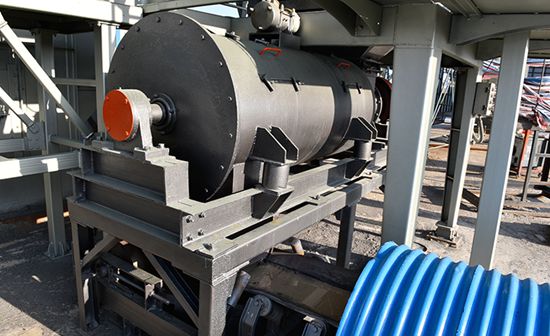

- Crushing Stage: Large pieces of fluorite ore are crushed to a fineness of 15mm-50mm by a crusher.

- Grinding Stage: The crushed material that meets the size requirements is fed into a grinding mill, such as HGM ultra fine grinding mill or CLUM vertical roller mill, and pulverized in the grinding chamber.

- Classification Stage: The ground material is classified by a separator, and unqualified powder is returned for re-grinding.

- Powder Collection Stage: The finely ground powder is collected through a powder collection system, and gas and powder are separated.

What are the primary industrial applications of fluorite powder, and how does its fineness affect its usability

Fluorite powder has various industrial applications, including in the metallurgical industry, glass production, and enamel manufacturing. The fineness of the fluorite powder is tailored to specific needs. For instance, 100 mesh, 200 mesh, 325 mesh, 600 mesh, 800 mesh, 1250 mesh, and finer powders are used in different applications. The fineness of the powder impacts its suitability for various processes and its effectiveness in removing impurities in steelmaking, as well as its role in the production of glass and enamel.

What is the significance of fluorite in industrial applications

Fluorite plays a significant role in various industrial applications. It is the primary source of fluorine, which is used in the production of hydrofluoric acid, a vital chemical in the aluminum smelting, aviation, and aerospace industries. Additionally, fluorine compounds derived from fluorite are used in the production of refrigerants, fire extinguishing agents, polymers, and more. Furthermore, fluorite finds applications in the glass, ceramic, cement, and building materials industries due to its flux and color-enhancing properties.

What are the main features and advantages of the HGM fine powder grinding mill and CLUM vertical roller mill in processing fluorite

The HGM fine powder grinding mill and CLUM vertical roller mill are both effective in processing fluorite and other non-metallic minerals. They offer the following features and advantages:

- Improved Grinding Efficiency: These mills have enhanced grinding curves and improved grinding efficiency, resulting in higher production capacity compared to alternative mills.

- Energy Efficiency: Both mills are energy-efficient, with lower energy consumption, reducing operational costs.

- Precision Control: They use PLC control systems and multi-head powder selection technology to precisely control grinding parameters, enhancing product quality.

- Maintenance Convenience: The mills feature reversible structures and hydraulic adjustment systems for easy maintenance and reduced downtime.

What role does fluorite play in the production of hydrofluoric acid, and what are the key applications of hydrofluoric acid in various industries

Fluorite is a key ingredient in the production of hydrofluoric acid. Hydrofluoric acid has diverse applications in various industries, including:

- Aluminum Industry: It is used to produce aluminum fluoride, artificial cryolite, sodium fluoride, and magnesium fluoride for aluminum production.

- Chemical Industry: Hydrofluoric acid serves as a raw material for organic fluorine compounds used in refrigerants, solvents, and polymers.

- Medicine: It is used in the production of fluorine-containing drugs and medical products.

- Refrigeration: Hydrofluoric acid reacts with carbon tetrachloride to produce refrigerants like Freon.

- Other Industries: It is employed in the manufacture of pesticides, preservatives, additives, and more.

How does the fluorite processing line ensure worker safety and prevent environmental pollution

The fluorite processing line is designed to prioritize worker safety and prevent environmental pollution through various measures:

- Enclosed Processing: The entire processing line is carried out in a fully enclosed negative pressure environment, minimizing dust exposure to workers.

- Dust Collection: Dust collectors are often installed to capture any dust generated during crushing and grinding, ensuring minimal environmental impact.

- Noise Reduction: Silencers and anechoic rooms are used to reduce noise levels, creating a more comfortable working environment.