What is the purpose of the classification stage in alunite processing

The classification stage plays a vital role in ensuring that the ground alunite powder meets the desired specifications. In this stage, the ground alunite powder is classified by a classifier, along with the system airflow. This classification process helps separate the fine powder from any larger particles. Any unqualified alunite powder is returned to the mill cavity of the main engine to undergo further grinding.

How is the qualified alunite powder collected in the alunite processing process

The final stage in the alunite processing process is the powder collection stage. In this stage, the qualified alunite powder is collected and separated from the gas and airflow. The collected finished powder is then conveyed to a finished product silo using a conveying device. This ensures that the high-quality alunite powder is stored and ready for use or further processing.

What are the main specifications and features of SBM's ultrafine mills

SBM's ultrafine mills offer various specifications and features, including:

For HGM series three-ring four-ring medium-speed micro-grinding mills:- Finished product fineness: 300-2500 mesh- Output: 0.2-45t/h- Suitable for processing non-flammable and explosive brittle materials with medium and low hardness- Arbitrary adjustment of finished powder fineness, suitable for grinding materials with Mohs hardness below 6- Small equipment investment, simple operation, and continuous 24-hour operation

For CLUM series ultrafine vertical roller mills:- Finished product fineness: 325-3000 mesh- Output: 0.2-45t/h- Ideal for ultra-fine grinding of white non-metallic minerals, providing high-quality fillers and additives for various industries- Achieves high whiteness, narrow particle size distribution, and excellent particle sphericityThese mills are designed to meet the diverse needs of industrial powder grinding applications.

What are the methods for the comprehensive utilization of alunite ore

The comprehensive utilization of alunite ore involves three main methods: the alkaline method, acid method, and acid-base combined method. These methods share a common process that includes ore crushing and grinding, roasting, extraction of potassium oxide and decomposition of sulfur trioxide, and the separation of aluminum and iron. The first step is the extraction of alunite through the crushing and grinding process. Alunite is a non-metallic ore with specific hardness and density, making it suitable for processing using industrial mills like the SBM ultrafine powder grinding mill.

What grinding mill should be chosen for producing alunite powder with different fineness requirements

For producing alunite powder with a fineness of 300 mesh or higher, an alunite ultrafine powder grinding mill, like the one offered by SBM, is the preferred choice. These mills can grind alunite into superfine powder within the range of 300-3000 mesh. If you require alunite powder with a fineness below 300 mesh, you can opt for an SBM Raymond mill. The choice of mill depends on the specific requirements of your application.

Explain the grinding stage in the processing of alunite ore.

The grinding stage follows the crushing stage and is a crucial step in the alunite processing process. During this stage, the feeding system delivers small pieces of alunite to the grinding chamber of the alunite ultrafine powder grinding mill. In the grinding chamber, alunite is ground into fine powder. The specific grinding principles can vary depending on the type of ultrafine mill being used.

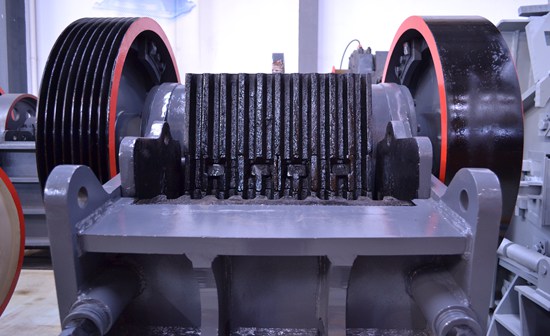

What is the role of the crushing stage in alunite processing

The crushing stage is the initial step in the processing of alunite ore. It involves breaking down large alunite stone into smaller particles suitable for further processing. This can be achieved using a variety of crushing methods, including jaw crushing, cone crushing, or hammer crushing. The goal is to reduce the size of the alunite to the fineness required for feeding into the mill, typically in the range of 15mm-50mm.

What is the global reach of SBM's products and its after-sales services

SBM's products are widely exported to more than 170 countries and regions around the world. With over 30 overseas branches and business organizations, SBM ensures efficient service and support to customers worldwide. The company holds 49 patents and 55 registered trademarks, establishing its reputation in the mining machinery industry in China. For a decade, SBM has ranked No. 1 in China's mining machinery industry, demonstrating its leadership and commitment to quality.

What are the thermoelectric properties of alunite, and how is it used to accelerate cement hydration

Alunite exhibits strong thermoelectric properties, making it useful in certain applications. When alunite is ground into a fine powder and added to cement, it serves as an accelerant for cement hydration. The effective ingredients in alunite powder are aluminum oxide and sulfur trioxide, which can enhance the hydration and hardening of cement. This makes alunite a valuable additive in the construction industry, particularly in the production of cement-based materials.

What are the services provided by SBM in the pre-sale, on-sale, and after-sale stages

SBM offers a comprehensive range of services to support its customers throughout the equipment lifecycle. These services include:

Pre-sale:- Assistance in equipment selection- Free arrangement of engineers for site surveys and plan design

On-sale:- Strict adherence to quality standards- Free logistics and transportation information- Implementation of standard preparation and delivery processes

After-sale:- Arrangement of engineers for on-site equipment installation and commissioning- Free technical guidance for equipment operation- On-site one-to-one operation, repair, maintenance, and training- A professional after-sales service team providing 24-hour customer support

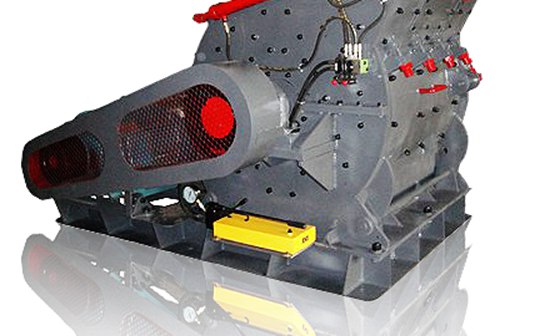

What are the key features of SBM's ultrafine mills for processing alunite and other non-metallic ores

SBM offers two main types of ultra-fine mills for processing non-metallic ores, including alunite: HGM series three-ring four-ring medium-speed micro-grinding mills and CLUM series ultrafine vertical roller mills. These mills are capable of grinding non-metallic ores with a Mohs hardness of less than 7, and their fineness can be adjusted within a wide range, typically between 300-3000 mesh. They are versatile and can process over 100 other non-metallic ores, such as dolomite, limestone, carbon black, mica, vermiculite, and marble. These mills are a trusted choice for producing ultra-fine alunite powder and other materials.

How is alunite used in various industries

Alunite is a valuable multi-element mineral resource with diverse applications. It serves as a raw material for the production of more than 40 chemical products. In industry, it is primarily used for refining alum and can also be comprehensively utilized to produce potassium sulfate, sulfuric acid, and alumina. Alum, derived from alunite, finds applications in printing, papermaking, tanning, paint, and other sectors. The potassium sulfate produced is chlorine-free and suitable for the cultivation of tobacco, fruit trees, and economic crops. Alunite can also be used in the preparation of potassium-nitrogen fertilizer using the ammonia-alkali method.

What is alunite, and what are its properties

Alunite is a trigonal sulfate mineral that is typically found in massive or earthy forms. Its crystal structure is not readily apparent, as it is a cryptocrystalline mineral. When pure, it appears white, but impurities can give it light gray, light red, light yellow, or reddish-brown colors with a glassy luster. Alunite is insoluble in water, slightly soluble in sulfuric acid, and completely decomposes in strongly alkaline solutions.