How does the CLUM superfine vertical mill work, and what is its production line composition

The CLUM superfine vertical mill operates by having its main motor drive the grinding disc through a reducer. The material to be processed is fed into the center of the grinding disc through various components, such as a hoist, screw conveyor, and feeding valve. Under the influence of centrifugal force, the material moves towards the edge of the grinding disc, where it is crushed by the pressure of the grinding roll and the shearing force between the grinding disc and the grinding roll. After passing through the grinding zone, the pulverized material is propelled into a multi-rotor powder separator for classification by high-speed airflow from a high-pressure fan. Material that doesn't meet the requirements returns to the grinding disc for re-grinding, while material that meets the criteria is collected and sent to storage.

What are the advantages of using the superfine vertical mill for light calcium powder production

The superfine vertical mill offers several advantages for light calcium powder production, including:

- Flexible fineness adjustment, high powder selection efficiency, and the production of fine powder with a good particle shape.

- High grinding efficiency and low energy consumption, ensuring stable operation.

- An intelligent control system that simplifies operation.

- Long service life for the grinding roller, as it's made from high wear-resistant materials.

- An environmentally friendly system that operates under negative pressure, equipped with a pulse dust collector to prevent dust pollution.

What materials can be processed using the CLUM superfine vertical mill

The CLUM superfine vertical mill is designed to process a variety of non-metallic ores. Some of the materials it can effectively grind include calcite, limestone, dolomite, feldspar, barite, kaolin, calcium carbonate, and marble. It's especially well-suited for grinding white non-metallic ores with a Mohs hardness below 7. The mill is capable of producing high-quality powder with desirable properties such as high whiteness, low iron content, high purity, and good sphericity.

What is the difference between heavy calcium powder and light calcium powder

Heavy calcium powder and light calcium powder are different forms of calcium carbonate. Light calcium powder, also known as precipitated calcium carbonate, is a white powder with a specific gravity of about 2.71. It is tasteless and odorless and has various industrial and medical applications. Light calcium powder can be used as a filler in industries like rubber, plastics, paper, coatings, and inks. It's also utilized in organic synthesis, metallurgy, glass production, and as an antacid for gastric and duodenal ulcers. It serves as an SO2 remover in waste gases containing sulfur dioxide, a feed additive for dairy cattle, and more. In contrast, heavy calcium powder is generally obtained from natural sources and has different properties and applications.

What are the key features and advantages of the CLUM superfine vertical mill

The CLUM superfine vertical mill is an industrial milling equipment that offers several key features and advantages. It integrates grinding, grading, collecting, and conveying, making it suitable for large-scale production of ultrafine powder. Some of its main features include a large output, high efficiency, low energy consumption, intelligent operation, and environmental friendliness. Additionally, this mill is ideal for grinding non-metallic ores with a Mohs hardness below 7, particularly white non-metallic ores. Due to its material layer grinding principle, it produces high-end powder with characteristics like high whiteness, low iron content, high purity, and good sphericity.

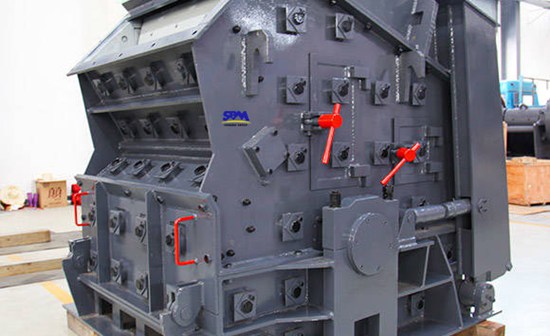

What are the components of the superfine vertical mill production line for light calcium powder

The production line for light calcium superfine vertical mill consists of two main systems: the milling system and the powder selection system. The milling system includes components such as a raw material primary crusher, elevator, screw conveyor, superfine vertical mill, multi-rotor powder separator, pulse dust collector, pneumatic conveying system, and packaging machine. The powder selection system comprises a multi-rotor ultra-fine powder separator, fan, pulse dust collector, and screw conveyor. These systems work together to process raw materials and produce high-quality light calcium powder.