What are the key stages in the production of barite powder

The production of barite powder involves several key stages:

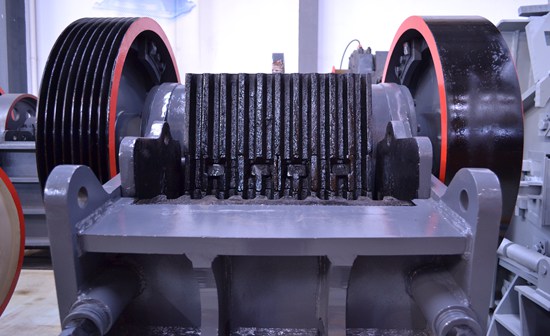

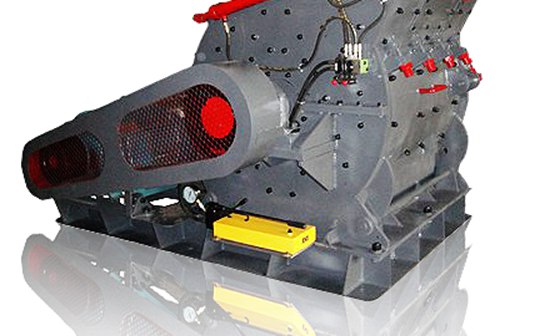

1. Crushing: Barite ore is initially crushed by a jaw crusher, followed by secondary crushing using a hammer crusher or impact crusher.

2. Sorting: Gravity separation is performed using a jig machine to separate barite ore based on particle size and other properties.

3. Grinding: The qualified barite particles are ground in an industrial ultrafine grinding mill to achieve the desired fineness.

4. Classification: Ground barite powder is sorted by a classifier within the grinding chamber.

5. Powder Collection: The final barite powder is collected using a pulse bag filter and then packaged for use or sale.

Is barite toxic to humans or the environment

Barite, specifically barium sulfate (BaSO4), is not considered toxic to humans when ingested because it is insoluble in water and acids. However, inhaling barite particles can lead to chest pain, coughing, and eye irritation. Prolonged exposure to barite dust may result in barium pneumoconiosis. Environmentally, barite dust can cause atmospheric pollution when released into the air.

How is barite used in various industrial sectors

Barite is used in several industrial sectors:- In the oil and gas industry, it serves as a weighting agent in drilling mud to control pressure and stabilize production.

- It is used in paints and coatings as a filler to enhance viscosity and product brightness.

- Barite is used in plastics to improve product hardness, acid and alkali resistance, and wear resistance.

- In the rubber industry, it acts as a filler to reduce costs and enhance product properties.

- Barite is used in the paper industry as a filler and coating material to improve whiteness and surface coverage.

- It finds applications in construction, paving, and nuclear facilities as well.

What is the main application of barite in industrial processes

Barite has various industrial applications, including its use as a weighting agent in oil drilling, a white pigment in paints (commonly known as lithopone), a filler in chemicals, papermaking, and textiles, and as a flux in glass production to enhance brightness. Additionally, barite can be used in construction, rubber, and plastic industries for various purposes such as improving product properties and reducing costs.

What are the advantages of the industrial ultrafine grinding mill for processing barite

The industrial ultrafine grinding mill offers several advantages for processing barite:

- It can grind barite to a fine powder with a high degree of fineness (up to 3000 mesh).

- It has a small footprint, simple operation, and stable performance.

- It is energy-efficient, environmentally friendly, and minimizes dust pollution.

- The material layer control valve helps maintain a stable production process.

- Refueling can be done without the need for shutdown, making maintenance convenient.

What are the options for choosing a suitable mill for processing barite

Choosing the right mill for processing barite depends on your specific production needs. Consider the following options:

- If you have a limited budget, you can opt for HGM series ultrafine grinding mills, which offer stable operation, simplicity, and cost-effectiveness.

- For higher-quality powder production, consider CLUM series vertical mills, which provide a larger output and produce high-end powder with excellent properties.

- When selecting a mill, take into account your processing requirements, budget, and downstream industry demands.