What economic benefits are associated with using the limestone ultrafine vertical mill

The limestone ultrafine vertical mill offers good economic benefits in several ways. It employs a multi-head powder separator principle with each rotor using frequency conversion speed regulation, allowing for precise control of grinding fineness within the selected range. This prevents the separation of inferior materials. Compared to other mills producing products of the same fineness, the limestone ultrafine vertical mill can achieve energy savings of 30% to 50%, leading to substantial economic advantages.

Can you explain the working principle of the limestone ultrafine vertical mill in detail

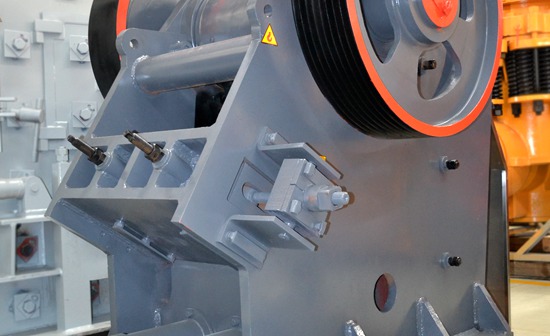

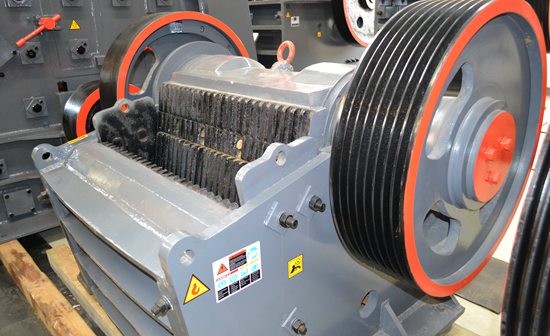

The limestone ultrafine vertical mill, specifically the CLUM Series, operates on a well-defined working principle. The main components of the mill include the motor, reducer, grinding roller device, grinding disc device, pressure device, powder separator, lubrication station, hydraulic station, and more. The motor drives the reducer, which in turn rotates the grinding disc. The material to be ground is fed into the center of the rotating grinding disc.

Under the influence of centrifugal force, the material moves towards the periphery of the grinding disc and enters the grinding roller table. Here, the material is crushed through a combination of extrusion, grinding, and shearing, driven by the pressure applied by the grinding roller.

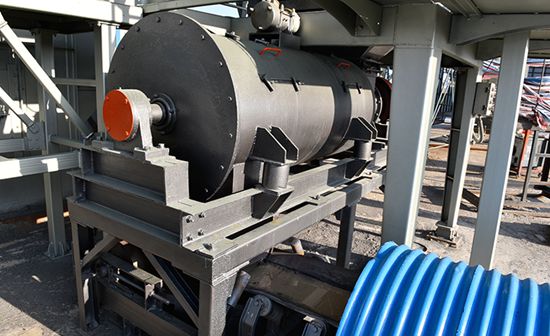

Simultaneously, high-speed airflow is injected evenly upwards from the air ring surrounding the grinding disc. This airflow lifts the pulverized material and coarser particles, blowing them back onto the grinding disc for re-grinding. The finer powder is carried by the airflow into a classification machine for separation, with the qualified fine powder collected by dust collection equipment as the final product. Unqualified coarse powder is returned to the grinding table, where it is re-ground with newly fed material, completing the grinding process cycle.

What environmental benefits does the limestone ultrafine vertical mill offer, and how does it achieve a high level of environmental protection

The limestone ultrafine vertical mill is designed with environmental protection in mind. It operates with low vibration and low noise. The equipment is sealed and works under negative pressure, preventing dust spillage and maintaining a clean working environment. It meets or exceeds national environmental protection standards. These features contribute to a high level of environmental protection during operation.

What types of materials can the limestone ultrafine vertical mill effectively process, and in which industries is it most suitable

The limestone ultrafine vertical mill is suitable for grinding non-flammable and non-explosive materials with a Moh's hardness under 6. This includes materials like gypsum, calcium carbonate, limestone, quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore, slag, cement clinker, zircon sand, fly ash, carborundum, and coal. It finds applications in various industries, including chemicals, metallurgy, and non-metallic ores. Notably, it excels in processing white superfine non-metallic ore powders, providing high-quality fillers and additives for applications in paper making, coating materials, plastics, rubber, PVC, printing ink, and more.

What are the key advantages of the limestone ultrafine vertical mill in terms of product quality

The limestone ultrafine vertical mill offers several advantages in terms of product quality. It employs a vertical abrasive layer principle, resulting in a short residence time for the material during grinding, reducing repeated grinding. As a result, the product has very low iron content, high whiteness, and purity. The finished products can achieve a powder content of less than 2μm, up to 70%, achieving 325 mesh low residue. Additionally, it allows for secondary powder selection to achieve a finer particle size for finished products.

What is the significance of the low-cost input features of the limestone ultrafine vertical mill, including automatic control and maintenance convenience

The low-cost input features of the limestone ultrafine vertical mill are notable for their convenience and cost-effectiveness. The mill is equipped with an automatic control system, enabling remote operation and ease of use. The use of PLC/DCS automatic control for roller pressure ensures precision control of grinding pressure without the need for manual operation. Additionally, the design of the mill minimizes wear, extends the service life of components, and allows for convenient and fast replacement of roller covers and lining plates, reducing downtime and associated losses.

How does the limestone ultrafine vertical mill achieve high grinding efficiency, and what role does frequency conversion play

The high grinding efficiency of the limestone ultrafine vertical mill is achieved through the control of the main engine speed using frequency conversion. This approach is versatile and suitable for various materials. The specially designed grinding curve of the roller sleeve and lining plate facilitates the formation of a material layer, making it easier to achieve the required product fineness in a single pass. The use of mechanical and electronic double limit protection devices effectively prevents direct contact between the roller sleeve and abrasive plate liner, avoiding destructive impact and violent vibration.