How does the fineness of attapulgite powder impact its use in different industries

The fineness of attapulgite powder significantly affects its suitability for various industries. Different applications require specific fineness levels to achieve optimal results. By offering a wide range of fineness options, SBM's industrial ore mills can cater to the diverse needs of downstream industries, ensuring that attapulgite powder can be effectively utilized in each application. This adaptability is essential for maximizing the utility of attapulgite in different industrial processes.

How do industrial ore mills like those developed by SBM contribute to attapulgite powder production

Industrial ore mills, such as those developed by SBM, play a crucial role in attapulgite powder production by offering the following advantages:

- Enhanced Grinding Efficiency: These mills feature a redesigned grinding curve that improves grinding efficiency, resulting in higher production capacity compared to other types of mills.

- Adjustable Fineness: SBM's mills can produce attapulgite powder with a wide range of fineness levels, from 150 to 3000 mesh, allowing for flexibility in meeting industry-specific requirements.

- Energy Efficiency: They consume significantly less energy, with only 30% of the energy consumption of jet mills, making them environmentally friendly and cost-effective.

- Dust Control: SBM mills are equipped with high-efficiency pulse dust collectors, ensuring a dust-free operation. Noise reduction features like silencers and anechoic rooms also enhance the working environment.

- Precision Control: Advanced technology and control systems enable precise adjustment of parameters like grinding pressure and speed, resulting in improved energy efficiency.

- Maintenance Convenience: The mills are designed with features like reversible structures and hydraulic adjustment systems, making maintenance and roller shell replacement easier and reducing downtime losses.

These characteristics make industrial ore mills an excellent choice for attapulgite powder production.

What is the attapulgite powder production process, and why is it divided into stages

The attapulgite powder production process involves several stages:

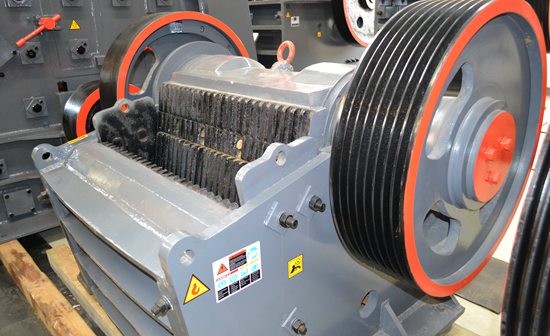

- Stage 1: Crushing - Large attapulgite is initially crushed using crushers like jaw crushers, impact crushers, or cone crushers to reduce the size of the raw material.

- Stage 2: Grinding - After crushing, the attapulgite is ground into a fine powder using an ultrafine grinding mill.

- Stage 3: Classification - The ground attapulgite powder is classified to separate fine powder from unqualified material, ensuring that only the desired fineness is sent to the finished product silo.

These stages are necessary to obtain high-quality attapulgite powder that retains its essential properties and meets the requirements of various applications. The division into stages ensures the effective processing of attapulgite ore.

What are the key features of industrial ore mills developed by SBM for attapulgite powder production

The industrial ore mills developed by SBM come with several key features that make them ideal for attapulgite powder production:

- Enhanced Grinding Efficiency: These mills feature a redesigned grinding curve that improves grinding efficiency, resulting in higher production capacity compared to other types of mills.

- Adjustable Fineness: SBM's mills can produce attapulgite powder with a wide range of fineness levels, from 150 to 3000 mesh, allowing for flexibility in meeting industry-specific requirements.

- Energy Efficiency: They consume significantly less energy, with only 30% of the energy consumption of jet mills, making them environmentally friendly and cost-effective.

- Dust Control: SBM mills are equipped with high-efficiency pulse dust collectors, ensuring a dust-free operation. Noise reduction features like silencers and anechoic rooms also enhance the working environment.

- Precision Control: Advanced technology and control systems enable precise adjustment of parameters like grinding pressure and speed, resulting in improved energy efficiency.

- Maintenance Convenience: The mills are designed with features like reversible structures and hydraulic adjustment systems, making maintenance and roller shell replacement easier and reducing downtime losses.

These features collectively contribute to the efficiency, environmental friendliness, and cost-effectiveness of attapulgite powder production using SBM's industrial ore mills.

What is the significance of different fineness levels in attapulgite powder

Attapulgite powder comes in various fineness levels, including 100 mesh, 200 mesh, 325 mesh, 800 mesh, 1200 mesh, 2000 mesh, 2500 mesh, and 3000 mesh. The choice of fineness is significant because it depends on the specific application. Different industries require attapulgite powder with varying fineness levels to achieve desired results. Having the flexibility to produce attapulgite powder at the required fineness is essential to meet the diverse needs of downstream industries.

What is attapulgite, and what are its main properties

Attapulgite, also known as Palygorskite, is a clay mineral with attapulgite as its primary component. It belongs to the sepiolite group of minerals and is a crystalline hydrated magnesium aluminum silicate mineral. Attapulgite is characterized by its strong water absorption, typically appearing white and opaque, with a Mohs hardness of 2-3. It possesses various valuable properties such as thickening, suspension, thixotropy, weather resistance, thermal insulation, and environmental friendliness. These properties make it suitable for a wide range of applications.

These applications leverage the unique properties of attapulgite, making it a valuable resource in various industries.