How does the kaolin ultrafine grinding mill contribute to various industries, and what types of materials can it grind into fine powder

The kaolin ultrafine grinding mill is an industrial machine used to grind hard stones into fine powder. It can process a wide range of materials, including calcite, talc, apatite, gypsum, fluorite, limestone, dolomite, diatomite, ceramic soil, clay, and marble. This versatile machine serves industries by providing the means to finely grind materials, making them suitable for various applications.

How does the kaolin ultrafine grinding mill process raw kaolin ore, and what are the resulting specifications of the processed material

The kaolin ultrafine grinding mill processes raw kaolin ore through several stages:1. Crushing stage: Large pieces of material are crushed to a fineness of 15mm-50mm by a crusher.2. Grinding stage: Material meeting the conditions for entering the mill is fed into the grinding chamber, where it is pulverized.3. Classification stage: The ground material is classified by a classifier, and unqualified powder is returned for re-grinding.4. Powder collection stage: The finished powder is collected, separated from the gas, and sent to a silo for packaging.The mill can produce kaolin with specifications ranging from 100 mesh to 2500 mesh, which can be used in various industries, including papermaking and ceramics.

What are the main products offered by the company mentioned in the text

The company's main products include the HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer, and matching hammer crusher.

What is the role of kaolin in the ceramic industry, and how does it affect the sintering process of ceramics

Kaolin in the ceramic industry increases the content of Al2O3, making the formation of mullite easier. This results in improved sintering strength and stability of ceramics. Kaolin also helps in forming a green body frame during the ceramics' sintering process, preventing deformation and widening the firing temperature range. Its plasticity, cohesiveness, and other characteristics enhance the formability of porcelain clay glaze, facilitating the processing of ceramic products.

What is the primary application of kaolin, and what are its properties that make it suitable for this application

Kaolin is primarily used in the papermaking, ceramics, and refractory materials industries. It is valued for its white color, fine texture, plasticity, and fire resistance, making it an ideal material for enhancing paper gloss, filling gaps between paper fibers, improving opacity, and serving as a paper filler and coating. Its properties, including a small particle size and high whiteness, are crucial for these applications.

What functions does kaolin serve in the cosmetics and pharmaceutical industries

Kaolin is used in cosmetics as an additive to enhance oil absorption, water absorption, and the affinity between cosmetics and the skin. It also improves emollient function. In the pharmaceutical industry, kaolin serves as a carrier and auxiliary agent for the formation of pharmaceutical tablets, contributing to their structure and performance.

What role does kaolin play in the cable industry, and how does it improve the electrical insulation of cables

Kaolin is used in the cable industry to enhance electrical insulation properties. It has a high resistivity after calcination at an appropriate temperature, which improves cable insulation. The surface modification of calcined kaolin enhances its dispersibility in polymer materials and creates a strong bonding interface between organic polymer materials, modifiers, and calcined kaolin. This ensures even dispersion in the cable, acting as a bridge and enhancing insulation.

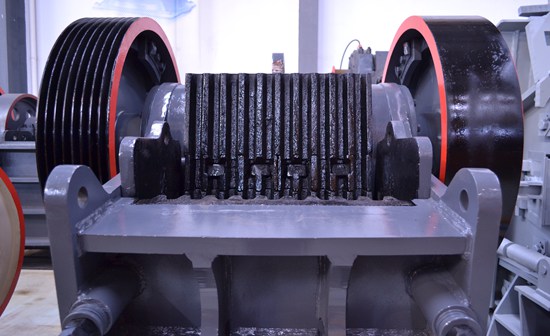

What are the two self-developed industrial milling machines recommended for grinding kaolin, and what is their range of application

The two recommended industrial milling machines for grinding kaolin are HGM ultrafine grinding mill and CLUM vertical roller mill. These machines can grind kaolin into a fine powder ranging from 200 to 3000 mesh. Additionally, they can process more than 100 other types of ores into fine and ultrafine powder. The choice between the two machines depends on specific production needs and materials. These machines offer simple operation, energy-saving features, environmental protection, and long service life.

How does kaolin contribute to the paper industry, and what are the key requirements for using kaolin in papermaking

Kaolin plays a significant role in the paper industry by improving paper gloss, enhancing fiber bonding, increasing opacity, and serving as a filler and coating material. The key requirements for using kaolin in papermaking include a particle size of less than 2μm and a whiteness greater than 86%. These properties make kaolin an excellent choice for enhancing the quality and performance of paper products.

What is the significance of kaolin in the paint industry, and how does it improve various aspects of coatings and paints

Kaolin is used as a filler in coatings and paints due to its white color, low price, good fluidity, stable chemical properties, and large surface cation exchange capacity. It improves the brushability, storage stability, moisture absorption, impact resistance, and anti-floating properties of coatings. Kaolin enhances the performance of coatings, especially in the development of high-quality, low-VOC, high-solid coatings, offering smoother, brighter, and more flawless results.

How is kaolin used in the rubber industry, and what benefits does it offer to rubber products

Kaolin is used as a filler in the rubber industry to enhance chemical stability, wear resistance, mechanical strength, and prolong the hardening time of rubber. It improves rheology, mixing, and vulcanization properties, increases the viscosity of unvulcanized products, and prevents issues like dents, collapse, sagging, and deformation. Kaolin enhances the water resistance, permeability, fire resistance, and chemical activity of rubber products, all while reducing costs without affecting performance.