What is the purpose of an eggshell powder making machine, and what are its key features

An eggshell powder making machine is designed to grind eggshells into fine powder with various applications. It can produce eggshell powder ranging from 150 to 3000 mesh. The machine offers several key features, including a small footprint, stable operation, safety, long service life, ease of operation, convenient maintenance, and environmental friendliness. It can also be integrated into a complete production line with conveyors, classifiers, powder collectors, balers, and more.

What are the advantages of using an eggshell powder making machine for eggshell processing

Using an eggshell powder making machine offers several advantages, including:

- Higher output and lower energy consumption compared to other grinding methods.

- Adjustable fineness between 150-3000 mesh, allowing for flexibility in product specifications.

- No rolling bearings or screws in the grinding chamber, reducing maintenance concerns.

- Pulse dust collector for environmentally friendly operation, meeting environmental protection standards.

How does the eggshell powder making machine work, and what is the process involved in producing eggshell powder

The eggshell powder making machine operates by passing the material through the gap between the grinding roller and grinding ring, effectively crushing and grinding the eggshells. The resulting powder falls onto a chassis and is blown to a classifier for further classification. If the fineness doesn't meet the requirements, it undergoes regrinding. Once the fineness meets the criteria, it flows into a pulse dust collector with the airflow, and the finished product is discharged through a discharge valve.

What are the benefits of implementing an eggshell powder production line, and how does it impact production efficiency and quality

Implementing an eggshell powder production line offers several benefits, including:

- Improved production efficiency and higher output.

- Enhanced product quality with uniform particle size and high purity.

- Reduced maintenance costs and downtime due to a low failure rate.

- Environmental friendliness with low dust emissions and reduced noise levels.

Can you explain the process flow of an eggshell powder production line, including the machinery and equipment used

The process flow of an eggshell powder production line consists of four main stages:

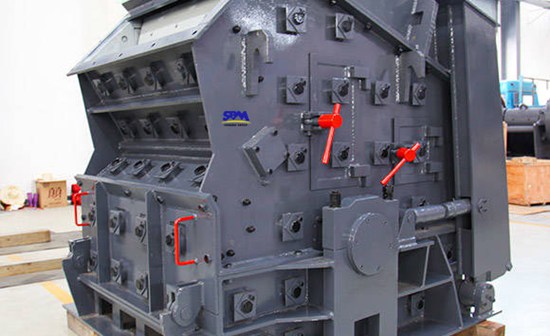

- Stage 1 - Crushing: Eggshells are coarsely crushed using a crusher to a size suitable for milling (10mm-50mm).

- Stage 2 - Milling: The crushed eggshell pieces are sent to the mill's grinding chamber for fine powder production using various equipment such as Raymond mills, high-pressure suspension roller mills, or other suitable machinery.

- Stage 3 - Collecting Powder: The powder meeting the desired fineness is separated and collected by the airflow through a dust collector, and it's then sent to the finished product silo.

- Stage 4 - Dust Removal and Packaging: Special dust removal equipment ensures low dust emissions, and the finished powder is uniformly packaged using a powder tanker or an automatic packing machine.

What are the steps involved in the eggshell powder production process, from collecting eggshells to obtaining the final product

The eggshell powder production process typically involves the following stages:

- Collecting eggshells and removing impurities.

- Milling the eggshells into powder using an eggshell crusher or industrial grinding equipment.

- Sieving and packaging the eggshell powder, ensuring uniform particle size and high quality.

What are the different methods for drying eggshells before processing them into powder, and how does each method work

Eggshells can be dried using two main methods:

- Natural drying: This method involves exposing the eggshells to the sun to evaporate moisture. It's essential to spread them thinly and avoid turning them initially to expedite moisture evaporation.

- Heating and drying: Eggshells are placed in a drying room with heating equipment, maintaining a temperature of 80-100°C to dry them in about 2 hours.

What are the potential uses of eggshell powder, and how does it contribute to sustainable development

Eggshell powder has various applications and can contribute to sustainable development by:

- Supplementing calcium deficiency in livestock and poultry feed.

- Being used in food calcium source addition, feed additives, daily chemical product processing, cleaning, fertilizer, and other fields.

- Reducing waste by repurposing discarded eggshells, thus promoting recycling ecology.