What are the advantages of using lamination-based crushing equipment for basalt

Using lamination-based crushing equipment, such as the basalt cone crusher, offers several advantages for basalt crushing:

- High efficiency and low wear, reducing production costs.

- Reshaping of small-grained stones to achieve a quality similar to natural sand and gravel.

- Improved stone quality for high-grade building projects.

These advantages make lamination-based crushing equipment a preferred choice for processing basalt.

What is basalt, and what are its key properties

Basalt is a type of volcanic rock known for its dark color, which is generally black but can also be grayish-green or dark purple. It exhibits a porphyritic structure, has a bulk density ranging from 2.8 to 3.3 g/cm³, and possesses a high compressive strength, often reaching up to 300MPa. Basalt is a durable and hard rock with a Mohs hardness rating of 5-7 and a silica dioxide (SiO2) content between 45% and 52%. These properties make it an ideal material for various applications, including construction.

What is the process for crushing basalt in a production line

The crushing of basalt in a production line typically involves several stages:

- Stage 1: Primary Coarse Crushing: Large basalt rocks are initially fed into a jaw crusher for coarse crushing.

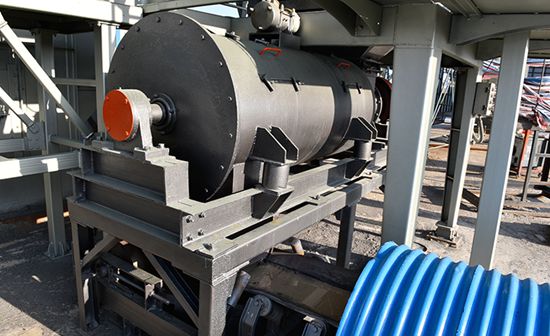

- Stage 2: Medium and Fine Crushing Treatment: The crushed materials from the previous stage are then fed into a cone crusher for medium and fine crushing.

- Stage 3: Material Screening: The materials crushed by the cone crusher are screened using a circular vibrating screen. Materials meeting size requirements are sent to the sand-making machine, while those that don't meet the requirements are recirculated for further crushing.

- Stage 4: Sand Making: Materials meeting the sand-making granularity requirements are processed in a sand-making machine to create the desired shape and size.

This process ensures that the basalt is crushed, screened, and shaped to meet specific requirements for various applications.

Why is it challenging to mine large basalt stones

Basalt mining is challenging when it comes to extracting large stones. Basalt has many joints and is brittle, making it difficult to obtain large stone blocks. This brittleness and the presence of numerous joints in the rock contribute to the complexity of mining operations.

What are the key applications of basalt in the construction and building materials industry

Basalt finds various applications in the construction and building materials industry due to its exceptional properties:

- Construction of roads, railways, and airport runways: Basalt is renowned for its strong compression resistance, low crushing value, high corrosion resistance, and excellent adhesion to asphalt, making it an ideal material for infrastructure projects.

- Building materials: Basalt's excellent compressive and flexural performance, good abrasion resistance, and low water absorption make it an excellent choice for indoor and outdoor decoration, including flooring, wall cladding, and more.

These applications leverage the unique qualities of basalt to create durable and aesthetically pleasing structures.

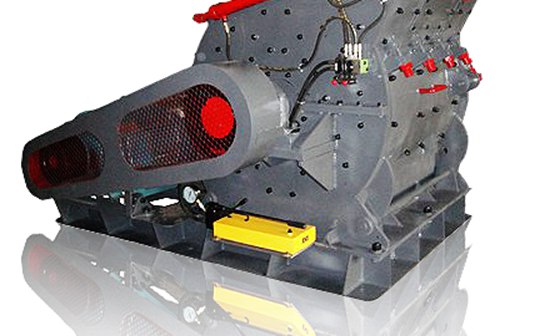

What equipment is commonly used for crushing basalt, and why

When crushing basalt, it is advisable to use specific equipment tailored to its properties. The impact crusher is generally not recommended for basalt crushing due to its strong hardness and high silicon content. Instead, the cone crusher is more suitable for medium and fine crushing operations in the second and third stages of the crushing process. This choice is made to reduce wear and tear on crucial parts, which can significantly impact crushing costs. Lamination-based crushing equipment, such as the basalt cone crusher, is often preferred to minimize wear on wear-resistant parts.