What are the two recommended types of feldspar grinding mills, and what are their advantages

There are two main types of feldspar grinding mills recommended for processing feldspar into fine powder:

- Ultra Fine Grinding Mill: This mill is designed for high-efficiency and low-power consumption. It has a small footprint, requires a relatively small initial investment, and ensures an environmentally friendly operation with minimal pollution. It is suitable for various applications like grinding feldspar, calcium carbonate, kaolin, bentonite, and more.

- Vertical Roller Mill (Ultrafine Vertical Roller Mill): This type of mill is ideal for mass production and delivers good quality finished products. It has strong drying capacity, capable of handling raw materials with a moisture content of up to 15%. Moreover, it prioritizes environmental protection in its operation.

What is the composition of feldspar and where is it commonly found

Feldspar is a group of aluminosilicate minerals that typically contain elements such as silicon dioxide (SiO2), aluminum oxide (Al2O3), potassium oxide (K2O), and sodium oxide (Na2O). It is a common rock-forming mineral found in various geological settings, including igneous rocks, metamorphic rocks, and sedimentary rocks. Feldspar is known for its diverse colors and glassy luster, and it constitutes a significant portion of the Earth's crust, accounting for up to 60% of its composition.

Can you explain the feldspar crushing and grinding process

The process of crushing and grinding feldspar involves several steps to prepare the raw material for various industrial applications. Here is a simplified overview of the feldspar crushing and grinding process:

- Feldspar Raw Ore: The process begins with the extraction of raw feldspar ore.

- Vibrating Feeder: The raw ore is fed into the process using a vibrating feeder.

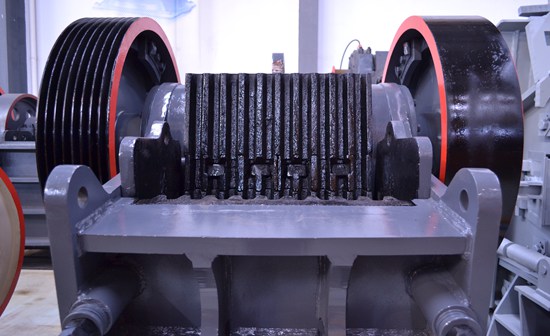

- Jaw Crusher (Preliminary Crushing): The raw ore undergoes preliminary crushing using a jaw crusher to reduce its size.

- Bucket Elevator: A bucket elevator is used to lift and transport the crushed material.

- Impact Crusher (Primary Crushing): The material is further crushed by an impact crusher.

- Bucket Elevator: Another bucket elevator is used for material transportation.

- Impact Crusher (Secondary Crushing): The material is subjected to secondary crushing using an impact crusher.

- Superfine Grinding Machine Equipment: The crushed material is further processed in a superfine grinding machine to reduce it to the desired fineness for specific applications.

- Bucket Elevator: A bucket elevator is again used to convey the processed material.

- Conveyor: The material is transferred using a conveyor system.

- Clinker Bin Cooling and Storage: The final product is stored in a clinker bin after cooling.

- Finished Products: The processed feldspar is now available as finished products ready for industrial use.

What are the primary industrial uses of feldspar powder

Feldspar powder is utilized in various industrial applications due to its composition and properties. The main applications of feldspar powder include:

- Ceramics Industry: Feldspar powder is a crucial raw material for producing ceramic products. It is used to make blanks and glazes for ceramics, enamels, and electric porcelains.

- Glass Industry: Feldspar is used in the glass industry to improve the transparency and durability of glass materials.

- Abrasives: In the abrasives industry, feldspar powder is employed to create abrasive materials for various applications.

- Chemical Industry: Feldspar powder can serve as a filler in coatings and is used in the formulation of urethane and acrylic substances.

- Other Industries: Feldspar powder finds applications in papermaking, refractory materials, machinery manufacturing, coatings, welding rods, and more.