What are some advantages of rock powder grinding mills for industrial applications

Rock powder grinding mills offer several advantages for industrial applications, including:

- Efficient size reduction, ensuring optimal material processing.

- Versatility in handling various materials.

- Precise particle size control for tailored end products.

- High grinding efficiency with minimal energy consumption.

- Low maintenance requirements, reducing downtime.

- Environmental friendliness through dust control and energy-efficient designs.

- A wide range of applications, from construction to agriculture and pharmaceuticals.

What types of materials can rock powder grinding mills handle, and why is this versatility important

Rock powder grinding mills are capable of handling a wide range of materials, from soft to extremely hard rocks, including limestone, quartz, marble, granite, and various ores. This versatility is essential because different industries and applications require the grinding of various materials. Being able to process a diverse range of materials makes these mills adaptable and versatile in meeting the needs of different production processes.

What is the key principle behind the operation of a rock powder grinding mill

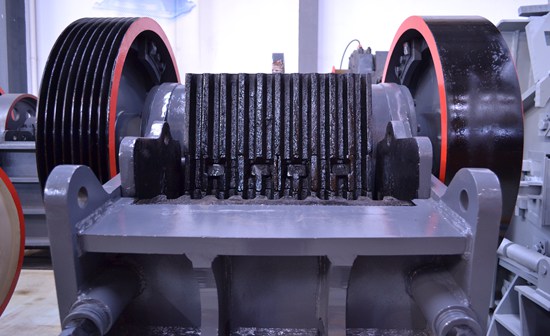

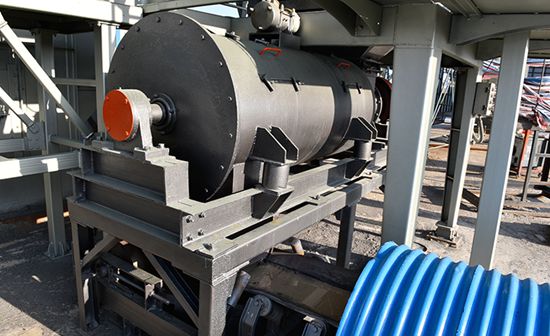

The fundamental principle behind the operation of a rock powder grinding mill is to use mechanical forces, such as impact, compression, and attrition, to break down rocks or minerals into smaller particles. Grinding media, like steel balls or ceramic beads, collide with the feed material inside the grinding chamber as the mill rotates. This collision and friction process reduces the size of the material, transforming it into fine particles or powder.

How do rock powder grinding mills offer precise control over particle size

Rock powder grinding mills provide precise control over particle size by allowing the adjustment of the grinding process. The mills can be customized to produce a specific range of particle sizes, whether it's coarse, medium, or fine powders. This control is achieved by modifying factors such as the type of grinding media, the speed of rotation, and the use of classifiers or screens to separate particles of the desired size.

What are the primary industries that utilize rock powder grinding mills

Rock powder grinding mills are primarily used in the mining and construction industries. They play a crucial role in grinding various types of rocks and minerals into powdered form, which can be further used as raw materials for cement production, additives in concrete, and more in the construction industry. These mills are also essential for processing ores and minerals in the mining sector.

How do ultrafine rock powder grinding mills differ from standard grinding mills

Ultrafine rock powder grinding mills, also known as ultra-fine grinding mills, are designed to produce much finer and more precise particle sizes compared to standard grinding mills. While the basic principles of size reduction remain the same, ultrafine mills are specifically engineered to achieve exceptionally fine and consistent particle sizes, making them suitable for applications where extreme precision is required, such as in some pharmaceutical and high-end manufacturing processes.