What makes perlite an environmentally friendly choice in various applications

Perlite is considered environmentally friendly in various applications due to several factors:

- Low Noise and Dust Emission: Compared to traditional grinding equipment, perlite superfine powder vertical mills generally produce lower noise levels and emit less dust, creating a more environmentally friendly working environment.

- Energy Efficiency: The energy-saving properties of perlite ultrafine powder vertical mills contribute to reduced energy consumption, which is environmentally beneficial.

- Versatility and Reduced Waste: Perlite's versatility in different applications can reduce waste and the need for multiple specialized materials, which is environmentally advantageous.

How does perlite's unique structure make it valuable in construction

Perlite's unique structure, characterized by its porous, lightweight, and expanded particles, makes it valuable in construction for several reasons:

- Insulation: The porous structure of perlite particles creates many interconnected air pockets, providing excellent insulation properties. This makes it ideal for use in insulating materials for buildings.

- Lightweight: Perlite is lightweight, which reduces the overall weight of construction materials. This is particularly beneficial in applications where weight needs to be minimized, such as lightweight concrete or plaster.

- Fireproofing: Perlite's ability to withstand high temperatures makes it useful for fireproofing applications in construction.

What are the advantages of using a perlite ultrafine powder vertical mill in grinding perlite

Using a perlite ultrafine powder vertical mill for grinding perlite offers several advantages:

- High Efficiency: The vertical arrangement of grinding rollers and turntables in the mill allows for efficient and uniform grinding of perlite particles, resulting in higher productivity and a finer particle size distribution.

- Energy Saving: Compared to traditional grinding equipment like ball mills or Raymond mills, perlite ultrafine powder vertical mills generally consume less energy during the grinding process.

- Adjustable Fineness: This type of mill provides the ability to control the fineness of the final product. The grinding table and separator speed can be adjusted to achieve the desired particle size distribution for perlite powder.

- Versatility: Perlite superfine powder vertical mills can be used to grind materials beyond perlite. They are suitable for processing various non-flammable and non-explosive ore materials with a Mohs hardness below 9.

- Compact Design: These mills have a compact design, saving space in production facilities. They require less space compared to other grinding equipment, making them suitable for both large industrial plants and smaller facilities.

- Low Maintenance Cost: Perlite ultrafine powder vertical mills are designed for long-term operation with minimal maintenance requirements. They have fewer moving parts than some other grinding equipment, reducing the likelihood of mechanical failures and the need for frequent repairs.

- Environmental Protection: In comparison to traditional grinding equipment, perlite superfine powder vertical mills generally produce lower noise levels and emit less dust. This makes them more environmentally friendly and enhances working conditions for operators.

What is the primary use of perlite in various industries

Perlite is utilized in several industries due to its unique properties. Some of its primary uses include:

- Agriculture: Perlite is used in agriculture to improve soil aeration and water retention. It is often added to potting mixes to enhance plant growth.

- Construction: In the construction industry, perlite is used as an aggregate in lightweight concrete and plaster. Its insulating properties make it valuable for construction applications.

- Manufacturing: Perlite is used in the manufacturing of various products, including insulation materials, fireproofing, and filtration products.

- Environmental Remediation: It is used to remediate contaminated soil and groundwater due to its ability to absorb and remove certain contaminants.

- Foundry and Metal Casting: Perlite is employed in foundry operations as a refractory material to withstand high temperatures during metal casting processes.

What is the Mohs hardness limit for materials that can be processed using a perlite ultrafine powder vertical mill

A perlite ultrafine powder vertical mill is suitable for processing materials with a Mohs hardness below 9. This means it can handle a wide range of non-flammable and non-explosive ore materials, making it versatile in various industrial applications.

What is the process involved in crushing and grinding perlite

The process of crushing and grinding perlite typically involves the following steps:

- Perlite Raw Ore: Raw perlite ore is the starting material for the process.

- Vibrating Feeder: The raw ore is fed into the process using a vibrating feeder.

- Jaw Crusher (Preliminary Crushing): The raw ore is initially crushed using a jaw crusher.

- Bucket Elevator: A bucket elevator is used to transport the crushed material to the next stage.

- Raw Material Warehouse: The crushed material is stored in a raw material warehouse.

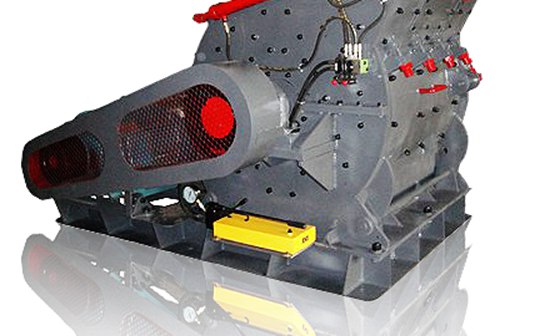

- Impact Crusher: The material undergoes further crushing using an impact crusher.

- Bucket Elevator: Another bucket elevator is used to move the material to the next stage.

- Impact Crusher (Secondary Crushing): The material is subjected to secondary crushing using another impact crusher.

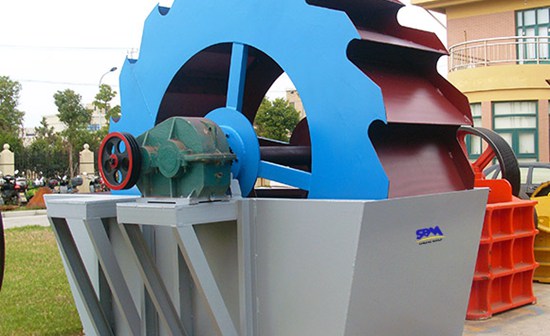

- Perlite Ultrafine Powder Vertical Mill Equipment: The crushed material is then processed in a perlite ultrafine powder vertical mill.

- Bucket Elevator: A bucket elevator is used again to transport the processed material.

- Conveyor: A conveyor is employed to further move the material within the production process.

- Clinker Bin Cooling and Storage: The material is cooled and stored in a clinker bin.

- Finished Products: The final product is ready for use or distribution.

How is perlite processed and expanded

Perlite is processed and expanded through a heating process. First, raw perlite ore is obtained. This ore undergoes several steps: it is crushed and ground into smaller particles, then subjected to high temperatures. As the obsidian in the perlite is heated, the water inside it evaporates, causing the material to expand and develop the porous structure with interconnected air pockets characteristic of perlite. This expanded perlite is then used in various applications.

How does the use of perlite in agriculture improve soil quality

The use of perlite in agriculture improves soil quality through its ability to enhance aeration and water retention. When perlite is added to soil or potting mixes, it creates air-filled cavities within the soil structure. This increased aeration benefits plant roots by providing them with oxygen and promoting root development. Additionally, perlite's porous structure allows it to retain moisture, preventing excessive water drainage and maintaining a consistent level of moisture in the soil, which is essential for plant growth.

What is the origin of perlite

Perlite is a naturally occurring volcanic glass that forms when obsidian, a type of volcanic glass, is heated rapidly at high temperatures. This heating process causes the water within the obsidian to evaporate, leading to its expansion and the creation of numerous tiny air-filled cavities.