How does the CLUM ultrafine vertical mill work, and what is the role of the various components in the milling process

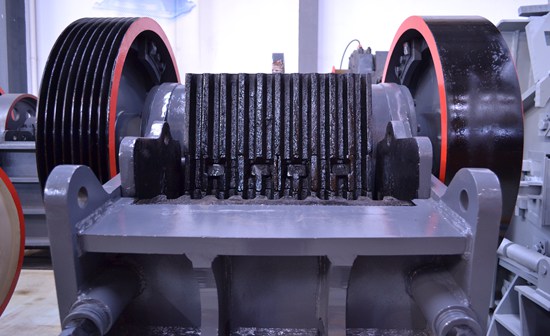

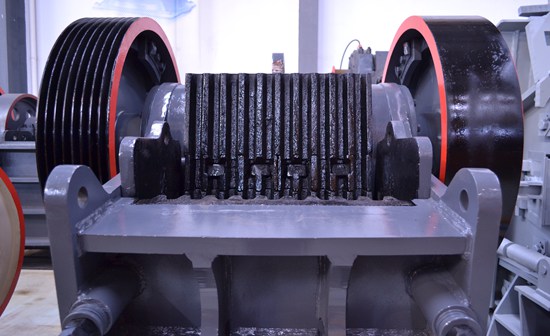

The CLUM ultrafine vertical mill operates by driving the grinding disc to rotate using a motor and reducer. The material to be ground is fed into the center of the rotating disc. Centrifugal force moves the material to the disc's periphery, where it encounters the grinding roller table. Under the pressure of the grinding roller, the material is crushed by extrusion, grinding, and shearing.

Simultaneously, high-speed airflow is sprayed upward from the air ring around the grinding disc. This airflow carries the pulverized material, with coarser material being blown back for re-grinding.

The fine powder is directed to a classification machine for separation, with the qualified fine powder collected as the product. Unqualified coarse powder is returned to the grinding table for re-grinding, completing the grinding process.

What are the key specifications of the CLUM ultrafine vertical mill, including its fineness range, output capacity, and applicable materials

The CLUM ultrafine vertical mill has the following key specifications:

- Adjustable fineness range: 150-3000 mesh

- Output capacity: 1-20 t/h

- It can grind non-metallic ores with Mohs hardness less than 7, such as calcite, gypsum, barite, and limestone, as well as dry and hard materials like shells, coconut shells, and cocoa shells.

What is the role of the secondary classification system in the CLUM ultrafine vertical mill, and what are its features

The secondary classification system in the CLUM ultrafine vertical mill is responsible for separating coarse powder from fine powder, and it consists of ultra-fine classifiers, fans, dust collectors, silos, screw conveyors, and pipes.

Key features of the secondary classification system include:

- High classification efficiency with the ability to adjust the fineness of finished products using frequency conversion speed regulation.

- Use of single-head and multi-head powder separators, allowing for flexible adjustment of finished product fineness.

- A wide range of fineness for sorted materials, ranging from 2um to 45um.

This secondary classification system enhances the mill's efficiency and product quality.

What is the primary function of the CLUM series activated carbon ultrafine vertical mill in industrial applications

The primary function of the CLUM series activated carbon ultrafine vertical mill in industrial applications is to perform ultra-fine grinding, which integrates grinding, powder separation, secondary classification, and pneumatic conveying. It avoids metal-to-metal impact and wear, resulting in high-purity ground activated carbon powder. This finely ground powder finds extensive use in various industries, including pharmaceuticals, fine chemicals, biopharmaceuticals, and more.

What are the advantages of the CLUM ultrafine vertical mill in comparison to other grinding systems in the industry

The CLUM ultrafine vertical mill offers several advantages, including:

1. High grinding efficiency and low energy consumption due to its high-efficiency classifier and the avoidance of over-grinding.

2. Intelligent and automatic control using an advanced Siemens PLC system, ensuring high-quality and consistently sized ultrafine powder.

3. Simplified technological process, large single-machine output, excellent sealing performance, and dust-free, clean operation.

4. Multiple methods for conveying finished products, including elevator and pneumatic conveying, making operation and control convenient.

5. Minimal vibration, low noise, and a sealed system operating under negative pressure, preventing dust spills and maintaining a clean environment.

6. Expert automatic control system that allows for easy remote and local control, saving labor and ensuring efficient operation.