What are some key improvements in the CLRM series enhanced roller grinding mill compared to the previous mill

Several key improvements have been made in the CLRM series enhanced roller grinding mill compared to its predecessor:

1. Optimized Grinding Part: The new mill has increased grinding pressure by 10% and expanded the grinding area by 15-20%. This optimization also includes an enhanced roller layout, providing a more efficient grinding space.

2. Triple Vibrating Damping: The mill incorporates triple damping to resist vibrations in the main unit base, volute airflow house, unit body, and grinding part, ensuring stable grinding conditions.

3. New Type Impeller of Classifier: The mill features a new cage-type impeller for the classifier, allowing the speed to be adjusted freely by a Variable Frequency Drive (VFD). This adjustment expands the output size range to 80-500 mesh.

4. Superimposed Multistage Seal: The grinding device in the CLRM series mill adopts a superimposed multistage seal, which extends the lubricating cycle, making maintenance more convenient and cost-effective.

What are some examples of the materials that can be processed using the CLRM series enhanced roller grinding mill

The CLRM series enhanced roller grinding mill is capable of processing a wide range of materials, including quartz, feldspar, barite, calcite carbonate, limestone, talc, ceramic, iron ore, carborundum, bauxite, rock phosphate, coal, and about 400 other kinds of materials. It is suitable for materials with a Moh's hardness of less than 6 and a humidity level below 6%.

Can you describe the workflow of the CLRM series enhanced roller grinding mill

The workflow of the CLRM series enhanced roller grinding mill is as follows:

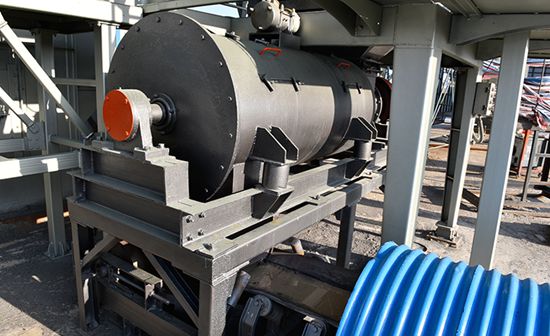

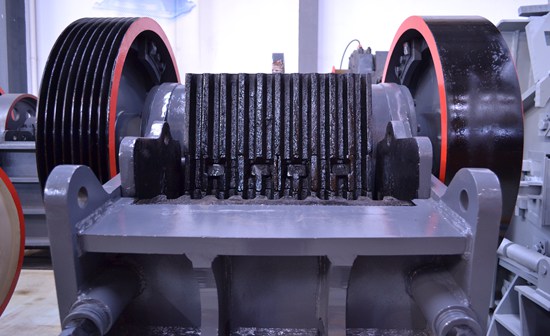

1. Big materials are crushed by a jaw crusher to the required particle sizes.

2. Crushed materials are carried by a bucket elevator to the storage hopper.

3. The materials are fed evenly and continuously by a vibrating feeder into the main unit for grinding.

4. The ground powder is carried by the airflow from the blower to the classifier for classification.

5. Particles meeting the desired fineness enter the cyclone collector through a pipe, where they are separated and collected.

6. The finished products are discharged at the discharging valve.

7. The airflow is sucked back to the blower through a return pipe on top of the cyclone collector.

The entire airflow system operates as a sealed circulation under positive and negative air pressure.

What is the primary purpose of the CLRM series enhanced roller grinding mill

The primary purpose of the CLRM series enhanced roller grinding mill is to process various non-flammable and non-explosive mineral materials with specific hardness and humidity characteristics. It is widely used in industries such as metallurgy, construction, chemical, mining, and highway construction. The mill is designed to grind these materials into fine powder with a controlled particle size, typically ranging from 80 to 500 meshes (180-30 microns).