What are the key features and differences between SBM's HGM series ultra-fine mills and CLUM series ultrafine vertical mills, and how should one choose between them for specific gypsum powder production needs

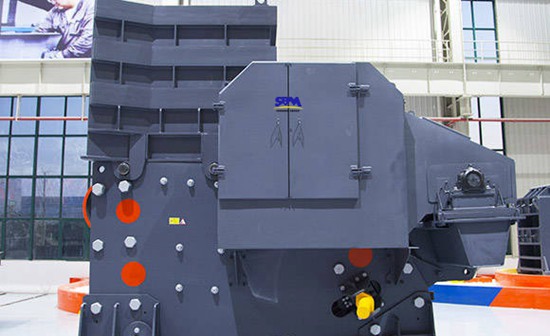

SBM offers two series of ultra-fine mills for gypsum powder production:

- HGM series ultra-fine mills: Suitable for producing gypsum powder below 2500 mesh. They are easy to operate, maintain, and have a smaller footprint. They are energy-efficient and environmentally friendly, making them a cost-effective choice for a wide range of non-metallic ores.

- CLUM series ultrafine vertical mills: Ideal for producing 3000 mesh gypsum powder. They have certain drying capacity and can be equipped with a secondary powder selection system. These mills produce a higher content of fine powder with superior finished powder quality, making them suitable for high-end powder production industries like coatings and papermaking.

The choice between these two series depends on the desired fineness, production volume, floor space, initial investment, and labor costs, among other factors. The selected mill should be able to meet the specific requirements of the gypsum powder production process.

What is the process for obtaining gypsum powder from gypsum stone ore, and how is the powder used differently based on its quality and intended applications

The process for obtaining gypsum powder from gypsum stone ore involves crushing and grinding the ore with an industrial ultrafine powder mill machine. The resulting gypsum powder can be used differently depending on its quality and intended applications:

- High-quality, impurity-free gypsum powder, known as "green gypsum," can be used directly without heating and dehydration. It is mainly used in food and chemical industries.

- Most other gypsum powder types need to be heated to remove water molecules, resulting in "Plaster of Paris." This type is primarily used in building materials, decoration, and various industries.

What services does SBM Ultrafine Powder Technology offer to its customers in addition to providing grinding machinery

SBM Ultrafine Powder Technology provides a range of services to its customers, including:

- Assistance in selecting the appropriate equipment for specific needs.

- Arrangement of engineers for on-site surveys and plan design.

- Strict quality standards implementation to guarantee product quality.

- Logistics and transportation information to offer more choices for delivery.

- Standardized stock preparation and rapid delivery processes.

- Technical guidance for equipment installation and commissioning.

- On-site one-to-one operation, repair, maintenance, and training.

- Professional after-sales service team with 24-hour response to customer needs.

These services ensure a comprehensive and satisfactory customer experience from pre-sale to after-sale, making SBM a trustworthy manufacturer in the industry.

What are the two main types of gypsum, and how do they differ in terms of composition and properties

There are two main types of gypsum: raw gypsum and anhydrite. Raw gypsum is calcium sulfate dihydrate, and it is characterized by its white or gray color, as well as its varying shades of red and brown. It exhibits a glass or silk luster and has a Mohs hardness of 2. Anhydrite, on the other hand, is anhydrous calcium sulfate and appears white or off-white. It has a glassy luster and a higher Mohs hardness, ranging from 3 to 3.5. These two types of gypsum can often be found together and can be transformed into one another under certain geological processes.

What is the main method for producing building gypsum powder, and how does it differ from other production methods

The main method for producing building gypsum powder is the "crushing, screening, and calcining kiln" one-step method. This process involves drying the raw gypsum, dehydrating it, crushing it, calcinating it, sorting it to remove impurities, and completing the modification, all in one step. This method results in gypsum powder suitable for use in various construction and industrial applications. It is a convenient and efficient approach to gypsum powder production.

How can gypsum be used to repair soil, and what role does it play in improving soil quality

Gypsum is an essential soil amendment for improving both acidic and alkaline soils. Its main component, calcium sulfate, interacts with sodium carbonate and sodium bicarbonate in the soil solution, leading to the formation of soluble sodium sulfate. This soluble salt can be washed away through irrigation, effectively eliminating soil alkalinity and improving soil quality. Gypsum is a valuable tool in agricultural practices for soil improvement.

What are the common industrial and construction applications of gypsum

Gypsum is a versatile industrial and construction material with a wide range of applications, including:

- Used as a cement retarder.

- In the production of gypsum building products.

- For model making.

- As a food additive in the medical and food industries.

- In the production of sulfuric acid.

- As a paper filler.

- In paint production.

- As plaster for construction purposes, including plaster of Paris.

- As a base material for painting.

What are the various uses of gypsum in agriculture and traditional Chinese medicine

Gypsum has diverse applications in agriculture and traditional Chinese medicine:

- In agriculture, it is used as a soil amendment to improve both acidic and alkaline soils. It can interact with sodium carbonate and sodium bicarbonate in the soil to produce soluble sodium sulfate, which can be washed away, effectively neutralizing soil alkalinity.

- In traditional Chinese medicine, gypsum is used for its pungent, sweet, and cooling properties. It is employed to clear heat, purge fire, eliminate irritability, quench thirst, promote astringency, and facilitate muscle growth.