What is talc, and what are its characteristics

Talc is a common silicate mineral known for its softness and creamy texture. It has a Mohs hardness of 1, making it one of the softest minerals. Talc is often found in block, leaf, fibrous, or radial forms and is typically white or off-white, although it can have various colors due to impurities. It's a hydrothermal alteration mineral, often forming from magnesium-rich minerals. Talc has a wide range of applications, including in refractory materials, papermaking, rubber fillers, cosmetics, and even traditional Chinese medicine.

What types of industrial ultrafine mills are commonly used to grind talc, and what are their specifications

Industrial ultrafine mills used for grinding talc include HGM ultra-fine ring roller mills and CLUM ultra-fine vertical mills. Their specifications and characteristics are as follows:

- HGM Series Ultrafine Grinding Mills: Suitable for non-metallic ores with a Mohs hardness less than 6, they produce finished products in the range of 300-2500 mesh, with an output of 0.2-45t/h. These mills are simpler, more efficient, have a small footprint, and are easier to maintain.

- CLUM Series Ultrafine Vertical Mills: These mills can grind non-metallic ores with a Mohs hardness less than 7 to up to 3000 mesh. They have a drying function and a secondary powder classification system. CLUM mills offer higher output and better powder quality, making them popular for high-end white powder production.

How is talc processed into talc powder, and what are the key stages of this process

Talc is processed into talc powder through a series of stages, which include selection, washing, air drying, crushing, grinding, powder selection, and collection. The key stages are as follows:

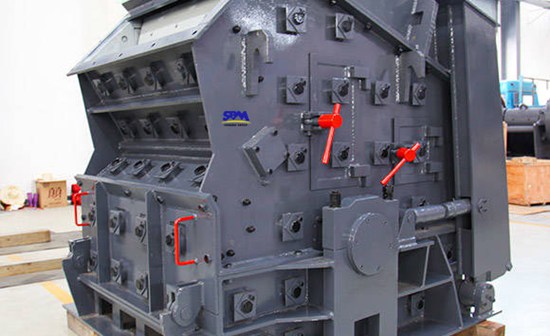

1. Crushing Stage: Large talc materials are initially crushed using a jaw crusher, followed by further crushing with a cone crusher to achieve the desired fineness.

2. Grinding Stage: Small talc pieces meeting grinding conditions are sent to the mill's grinding chamber, where they are ground into powder. The choice of the right mill is crucial in this stage.

3. Classification Stage: After grinding, talc powder is classified by a classifier. Unqualified powder returns for re-grinding.

4. Powder Collection Stage: Talc powder meeting the desired fineness is collected and stored for packaging. It's separated from the airflow in this stage.

What are the common uses of talc powder in different industries

Talc powder has diverse applications in various industries, such as:

- Cosmetic Grade: Used in emollient powder, beauty products, and talcum powder.

- Medicine-Food Grade: Found in medicinal tablets, sugar coatings, prickly heat powder, traditional Chinese medicine, and food additives.

- Paint Grade: Used in white body pigments and various coatings.

- Papermaking Grade: Serves as a filler for different paper and cardboard types.

- Cable Grade: Enhances cable rubber and serves as a cable isolating agent.

- Ceramic Grade: Used in the manufacture of various ceramics.

- Plastic Grade: Acts as a filler for different plastic types.

- Rubber Grade: Used for rubber packing and anti-sticking agents.

Talc is versatile and can be tailored to specific needs in these industries.

Can you explain the services provided by Shibang Industrial Technology Group Co., Ltd. in the context of the text

Shibang Industrial Technology Group Co., Ltd. is an international enterprise specializing in equipment research, development, production, sales, and service in various fields, including mine crushing, construction crushing, tower sand making, and industrial milling. The company offers a range of services:

- Pre-sale: Assisting customers in selecting the right equipment, arranging engineers for site surveys and plan designs.

- On sale: Strictly implementing quality standards, ensuring the quality of products, providing logistics and transportation information, and ensuring timely delivery.

- After-sale: Offering services such as equipment installation and commissioning, one-to-one operation guidance, repair, maintenance, and training. The company has a professional after-sales service team to respond to customer needs.

Shibang Industrial Technology Group Co., Ltd. aims to provide comprehensive support throughout the equipment's life cycle.

What precautions should be taken when using talc, and what are the potential health risks associated with it

Talc is generally safe when used in compliance with prescribed dosages and industry standards. However, long-term, excessive intake of talc can be carcinogenic. Therefore, it's essential to use talc products according to recommended guidelines and avoid excessive exposure. Talc is commonly used in cosmetics, pharmaceuticals, and various industrial applications, but users should be aware of any potential health risks associated with misuse.