What are the key features of HGM90 Ultra Fine Grinding Mill

1. High Efficiency: The product capacity of HGM90 Ultra Fine Grinding Mill is twice that of a jet mill and agitation mill with the same final size and power.

2. Longer Lifetime of Spare Parts: The roller and ring are made of special materials that significantly improve grinding efficiency, resulting in a longer lifespan for wearing parts, which can last over a year or 2-5 times longer than other types of mills.

3. High Safety and Reliability: The absence of rolling bearings and bolts in the grinding cavity reduces the risk of problems caused by bolts shedding or wear of bearings and seal components.

4. High Fineness of Products: HGM90 Ultra Fine Grinding Mill can achieve a product fineness as fine as D97≤5μm.

5. Environment-Friendly: The use of pulse dust collectors and mufflers helps reduce dust pollution and noise, meeting national environmental protection standards.

Who manufactures the HGM90 Ultra Fine Grinding Mill, and what can you tell us about the manufacturer

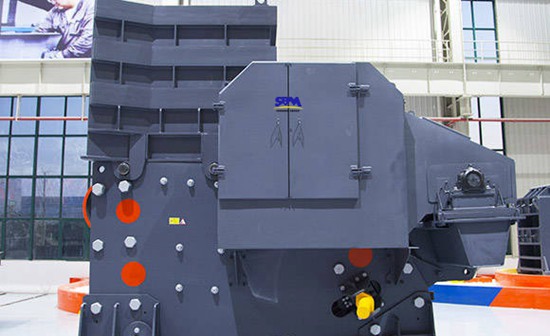

The HGM90 Ultra Fine Grinding Mill is manufactured by Shibang Micro Powder Technology Co., Ltd. This company is an established and reputable manufacturer specializing in ore grinding equipment. They have a strong presence in the field of ultra-fine grinding.

Shibang Micro Powder Technology Co., Ltd. is committed to providing the best service to its customers. They have built a large, systematic, and standardized service guarantee system to ensure that every aspect of their service is implemented accurately and efficiently.

The company takes customer feedback seriously and has a dedicated after-sales return visit team with over 100 members. This team not only resolves project-related issues promptly but also collects customer feedback and suggestions to drive continuous improvement in equipment development.

Shibang Micro Powder Technology Co., Ltd. also offers full life cycle services, including testing, debugging, and technical guidance to users. They aim to address any problems that may arise after a customer's project is completed, ensuring a comprehensive and ongoing commitment to customer satisfaction.

What is the primary application of HGM90 Ultra Fine Grinding Mill

HGM90 Ultra Fine Grinding Mill is primarily applied to non-inflammable, non-explosive, and brittle materials with a Mohs hardness under six. It can be used for grinding materials like calcite, chalk, limestone, dolomite, kaolin, gypsum, and more, totaling over 100 different types of materials. The product fineness can be controlled within the range of 325 to 2500 mesh.

Can you explain the working principle of HGM90 Ultra Fine Grinding Mill

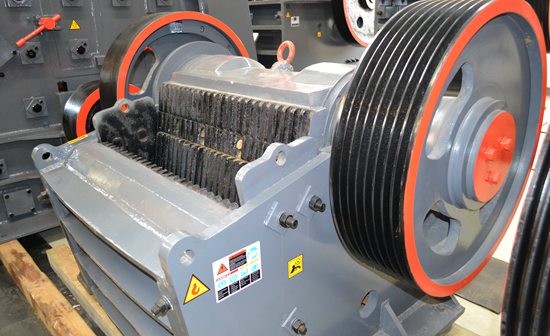

The HGM90 Ultra Fine Grinding Mill operates through a system where the main bearing and dials are driven by an electromotor connected to a reducer. Rollers within the mill rotate in a ring, driven by dials through a plunger. After being crushed by a hammer crusher, large materials are reduced to smaller particles and then sent to a storage hopper by an elevator. Electromagnetic vibrating feeders evenly distribute the material to the first dial's center. Centrifugal force drives the material to the edge of the dial, where it falls into the ring, crushed and ground by the rollers, ultimately becoming a fine powder. A high-pressure centrifugal blower inhales air from outside, blowing the crushed materials to a classifier. Coarse materials return to the mill for further grinding, while the finer particles mix with air and are discharged through a cyclone into a bin. Impulse dusters and blowers purify the air, reducing pollution and noise.