What is the main purpose of the three-ring medium-speed micro powder mill

The main purpose of the three-ring medium-speed micro powder mill is to grind materials into ultra-fine particles, with a typical particle size of over 3000 mesh. It is commonly used for processing ultra-fine powders and is suitable for a wide range of materials with medium to low hardness.

What materials is the three-ring medium-speed micro powder mill suitable for processing

The mill is suitable for processing non-flammable and explosive brittle materials with a medium to low hardness, with a Mohs hardness of less than 6. Examples of suitable materials include calcite, chalk, calcium carbonate, kaolin, and many others such as talc, mica, and barite.

What precautions should be taken when using the three-ring medium-speed micro powder mill

When using the mill, it's important to frequently check the bearing temperature, ensure the transmission belt is properly tensioned, inspect and maintain transmission parts, and monitor the pneumatic components for air leaks and damage. These precautions help ensure the efficient and safe operation of the mill.

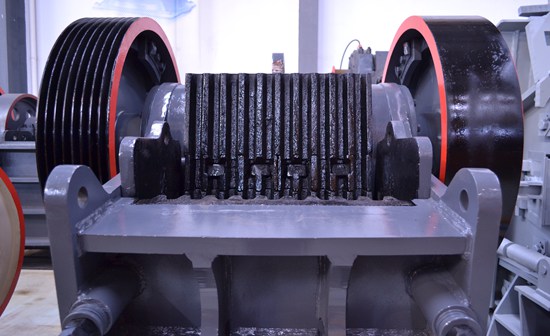

What is the working principle of the three-ring medium-speed micro powder mill

The mill breaks bulk materials into small particles using a hammer crusher, stores the material in a bin, and then feeds it to the turntable through a vibrating feeder. The material is dispersed to the periphery of the circle under centrifugal force and falls into the grinding ring's raceway. It is then impacted, rolled, and ground by the ring roller, becoming powder. The high-pressure fan draws external air into the machine and carries the crushed material into the powder classifier for further processing.

How does the three-ring medium-speed micro powder mill achieve energy efficiency

The three-ring medium-speed micro powder mill achieves energy efficiency by having an output that is more than double that of other mills (jet mill, stirring mill, and ball mill) with the same motor power and finished product fineness. This efficiency is due to the use of special materials for the grinding rollers and grinding rings, which greatly improves their durability.

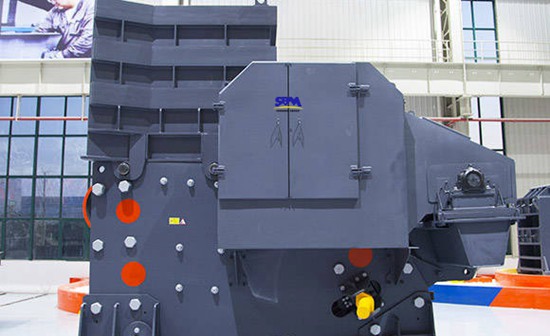

What components make up the complete configuration of the three-ring medium-speed micro powder mill

The complete configuration of the mill includes a hammer crusher, bucket elevator, storage bin, vibrating feeder, micro powder mill host, frequency conversion classifier, double cyclone powder collector, pulse dust removal system, high-pressure fan, air compressor machine, and an electrical control system.

How does the three-ring medium-speed micro powder mill ensure environmental protection and cleanliness

The mill employs a pulse dust collector to capture dust, and a muffler is used to reduce noise. This combination of features ensures that the mill operates in an environmentally friendly and clean manner, minimizing dust and noise pollution.

What are some key features of the three-ring medium-speed micro powder mill

Some key features of the three-ring medium-speed micro powder mill include energy efficiency, long service life of wearing parts, high safety and reliability, and environmental protection. It has a unique design, small footprint, and the ability to adjust the finished powder's particle size between 325-3000 mesh.