What are some of the applications of pumice stone in various industries

Pumice stone finds application in a wide range of industries. It is used in construction, gardening, the textile industry, garment factories, denim garment washing plants, washing and bleaching plants, dyeing and finishing plants, among others. Additionally, pumice is utilized in skincare and foot care to effectively remove the residual stratum corneum from the skin. In traditional Chinese medicine, it is known for its medicinal properties, including clearing the lungs and fire, resolving old phlegm, distilling water, and softening and dispelling nodules.

What is pumice, and what are its main characteristics

Pumice is a mineral formed by cooling magma after a volcanic eruption. It is primarily composed of silica and is known for its porous and lightweight nature. Pumice possesses several key characteristics, including high strength, resistance to acids and alkalis, corrosion resistance, pollution-free properties, and non-radioactivity, making it an environmentally friendly and versatile product.

What is the production process of pumice ore powder, and what are the key steps involved

The production process of pumice ore powder involves several key steps:

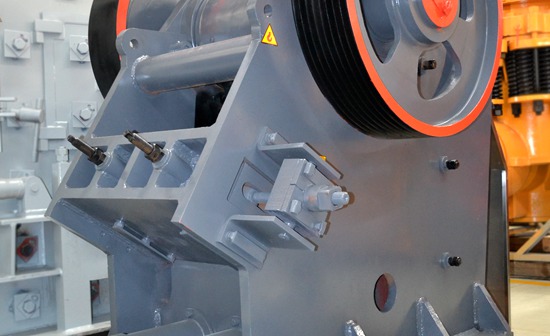

- Primary Crushing: Pumice is initially crushed into fine materials through a crusher and stored in a storage bin.

- Conveying: The crushed pumice is conveyed to the main grinder through a belt feeder.

- Grinding: The pumice material is ground into fine powder by the grinding ring and roller in the grinding host.

- Powder Selection: High-pressure wind generated by a fan blows the pumice powder through a screen on the top of the mill. Qualified powder passes through, while unqualified powder is ground again until it meets the required fineness.

- Collection: The pumice powder meeting the standard fineness is collected in a dust collector and can be loaded into a packaging machine.

What are the potential applications of pumice powder in different industries

Pumice powder has diverse applications in several industries:

- Building Materials: Pumice can serve as a natural lightweight aggregate for concrete, non-clinker cement, building finishing materials, and sound insulation and heat preservation materials.

- Chemical Industry: It is used as a filter, desiccant, catalyst, and molecular sieve storage enzyme carrier in the petrochemical industry.

- Plastics and Filler Industry: Pumice powder is employed as an abrasive in optical glass, plastic polishing agents, rubber fillers, and fillers in toothpaste and soap production.

- Other Applications: Pumice is used as an insecticide carrier, a fertilizer control agent, and in various environmental applications such as water purification and aquarium maintenance.

How can one select the appropriate pumice industrial powder grinder mill for specific needs

The choice of a pumice industrial powder grinder mill depends on the required fineness of the pumice powder:

- For pumice powder below 500 mesh: Raymond mill is a cost-effective option with a history of performance improvements over generations, providing good value for general fine powder production.

- For 300-2500 mesh pumice powder: HGM series ultrafine grinding machines are recommended, offering high efficiency, low consumption, and simplified powder processing procedures.

- For 3000 mesh superfine pumice powder: CLUM series vertical roller mills are the ideal choice, designed for large-scale ultra-fine dry powder processing of non-metallic minerals like pumice.

What are the different types of equipment used to grind pumice, and what are their advantages

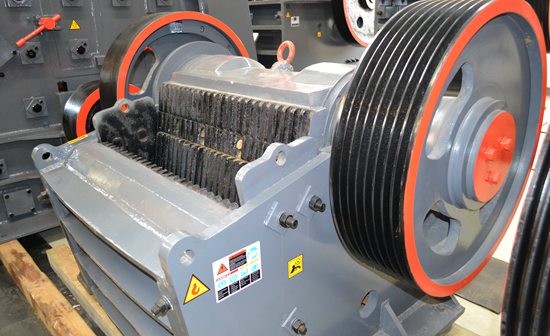

There are two primary types of equipment used to grind pumice:

- HGM Series Ultrafine Grinding Mill: This equipment is suitable for grinding pumice and other non-metallic ores. It offers adjustable fineness between 300-2500 mesh, has a small investment, compact design, simple operation, and convenient maintenance, resulting in cost savings, high efficiency, and a long service life.

- CLUM Series Ultrafine Vertical Mills: These mills are widely used in various industries and can grind pumice to a fineness of up to 3000 mesh. They provide high efficiency, good powder shape, and are especially suitable for high-end white powder applications.