What distinguishes SBM's Carbon Black Ultrafine Powder Mill and its advantages

SBM's Carbon Black Ultrafine Powder Mill offers several advantages:

- Fineness range of 150-3000 mesh

- Output ranging from 0.2 to 45t/h

- Suitable for non-metallic minerals with Mohs hardness less than 6

- Features larger output and higher fine powder content compared to other mills

- Equipped with a secondary powder selection system for high-quality, fine powder production

What are the key features of SBM's Powder Surface Coating Machine in modifying carbon black powder

SBM's Powder Surface Coating Machine offers the following features for modifying carbon black powder:

- Realizes surface modification to enhance application performance

- Produces high-quality modified powder

- Can be directly integrated into the production line plan

- Produced and sold directly by the factory, ensuring reasonable pricing and cost-effectiveness

What are the different stages involved in processing carbon black powder

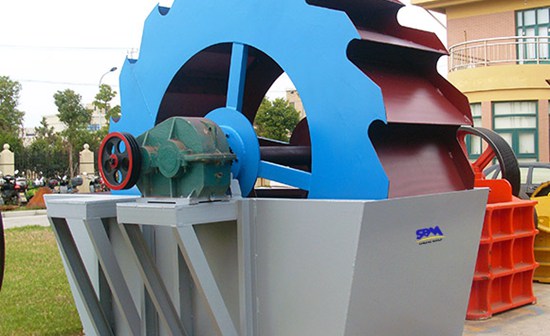

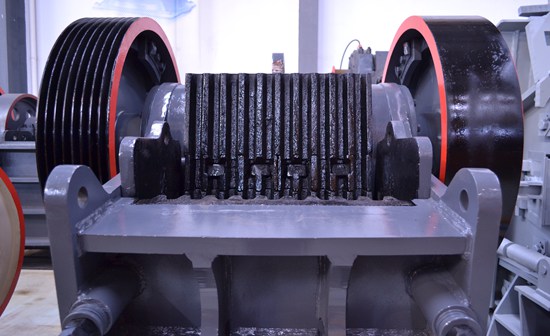

The processing of carbon black powder involves four main stages:

1. Crushing: Raw carbon black ore is crushed into small particles using a jaw crusher.

2. Grinding: Carbon black particles are ground into powder using a grinding mill.

3. Powder Classification: High-pressure fans separate coarse and fine carbon black powder.

4. Powder Collection: Ultra-fine carbon black powder meeting requirements is collected, while remaining dust is purified and discharged.

What are the advantages of SBM's ultrafine powder technology in carbon black milling

SBM's ultrafine powder technology offers several advantages in carbon black milling:

- Small footprint and simple operation

- Stable operation and long service life

- High efficiency and energy-saving

- Environmental protection with no dust pollution

- Material layer control valve for enhanced production stability

- Refueling without the need for shutdown, making maintenance convenient

What is the role of a bucket elevator and an electromagnetic vibrating feeder in carbon black processing

A bucket elevator is used to lift crushed materials to a storage bin, facilitating the movement of materials in the production line. An electromagnetic vibrating feeder continuously and quantitatively transports carbon black to the mill, preventing feed port clogs and improving production efficiency.

How can surface modification enhance the dispersion stability of carbon black powder

Surface modification can enhance the dispersion stability of carbon black powder by modifying its elemental composition and surface functional groups. This can be achieved through methods like graft modification, fatty acid modification, oxidation modification, and encapsulation modification. Surface modification improves the application performance of carbon black and its compatibility with various materials.

What are the categories and uses of carbon black

Carbon black can be categorized into three types based on its purpose and characteristics:

- Rubber Carbon Black: Used in the tire manufacturing industry, rubber seals, and shock absorbers to reinforce and fill rubber products.

- Pigment Carbon Black: Primarily used as a black pigment in inks, paints, and other industries.

- Conductive Carbon Black: Utilized in products that require low or high resistance properties, such as conductive rubber and radio components.

How can carbon black powder be modified to improve its dispersion stability

Carbon black powder can be modified to enhance its dispersion stability through various methods, including:

- Graft Modification

- Fatty Acid Modification

- Oxidation Modification

- Encapsulation Modification

Additionally, a powder modifier can be added during the grinding process, or surface coating machines can be used to achieve surface modification and improve application performance.

What are the primary applications of carbon black of different finenesses

Carbon black of different finenesses has various applications:

- 300 mesh: Used as a reinforcing agent in rubber products like tires and seals.

- 400 mesh: Commonly used in the rubber industry.

- 800 mesh: Suitable for applications in ink and paint as a black pigment.

- 1200 mesh: Used in radio components and conductive rubber due to its conductivity properties.

- 2500 mesh and above: Employed in high-end fillers for papermaking and coatings.

What is the role of the ultrafine industrial grinding mill in carbon black processing

The ultrafine industrial grinding mill is the primary equipment for grinding carbon black. It can grind carbon black to a fine powder ranging from 150 to 3000 mesh. This equipment is essential for achieving the desired fineness and characteristics of carbon black for various applications, such as in rubber, coatings, and more.