What is diatomaceous earth, and what are its main chemical and mineral compositions

Diatomaceous earth is a naturally occurring substance known for its various properties. Its primary chemical composition is mainly SiO2 (silicon dioxide), and its mineral composition consists of opal and its variants. This versatile material can be found in colors ranging from white, off-white, gray to light gray-brown. It possesses characteristics such as being fine, loose, lightweight, porous, with excellent water absorption, and strong permeability.

What is the geological origin of diatomaceous earth, and how does it relate to the history of life on Earth

Diatomaceous earth has a geological origin and is formed from the remains of single-celled diatoms, a type of marine or freshwater algae. These diatoms lived in seawater or lake water and played a crucial role in the early history of life on Earth by providing oxygen through photosynthesis. Over thousands of years, the accumulation of diatomaceous earth deposits formed, creating a valuable natural resource.

Can you describe the stages involved in the production of diatomaceous earth powder using an ultrafine grinding mill

The production of diatomaceous earth powder using an ultrafine grinding mill involves several key stages:

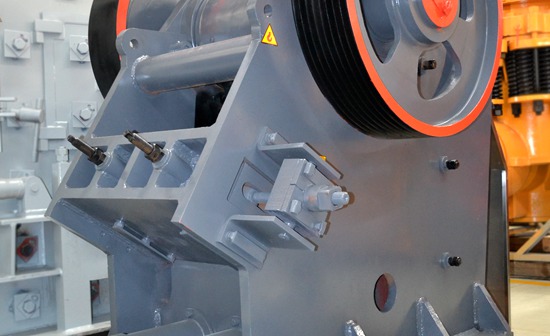

- Stage 1: Crushing - Raw diatomite ore is crushed into small particles by a jaw crusher and stored in a bin.

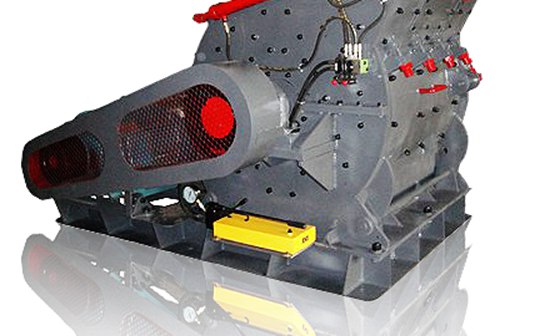

- Stage 2: Grinding - The diatomite particles are ground into a fine powder by a grinding mill through the action of centrifugal force.

- Stage 3: Powder Classification - A high-pressure fan is used to classify the pulverized diatomite powder, separating the coarse particles for regrinding.

- Stage 4: Collecting Powder - The ultrafine diatomite powder that meets the requirements is collected in a cyclone powder collector and then packed for further use.

What is the role of the powder modification process in enhancing the properties of diatomaceous earth

The powder modification process plays a vital role in improving the properties of diatomaceous earth. It can enhance various properties more effectively, making the material more suitable for specific industrial applications. Powder modification can be achieved by adding a modifier during the grinding process or by using specialized equipment like powder surface coating machines, resulting in improved application performance.

How does diatomaceous earth function as a catalyst carrier

Diatomaceous earth is an ideal catalyst carrier due to its suitable specific surface area, high porosity, abrasion resistance, acid resistance, and heat resistance. It serves as a platform for various catalytic reactions, including hydrogenation, oxidation, hydration, dehydrogenation, and reduction. These properties make it an excellent choice for supporting catalysts in industrial processes.

What are some common uses of diatomaceous earth in filtration and purification processes

Diatomaceous earth is widely used in filtration and purification processes in various industries. It is employed in the beer industry, pharmaceutical industry, water purification, oil industry, mailing solutions, coatings, dyes, fertilizers, acids, alkalis, seasonings, sugars, alcohol, and other filtration applications to remove impurities and particles from liquids and gases.

Is diatomaceous earth safe for humans and animals

Yes, diatomaceous earth is safe for both humans and animals. It is non-toxic and harmless when used as intended. In addition to its safety, it offers various benefits, such as its ability to prevent diseases, repel insects, remove odors, and provide valuable minerals and nutrients. It has a long history of safe use in various applications.

What role does diatomaceous earth play in creating environmentally friendly building materials

Diatomaceous earth's unique structure and properties make it an excellent choice for environmentally friendly building materials. It is used in diatom mud ecological wall materials. Diatomaceous earth is non-toxic, helps regulate humidity, eliminates odors, and keeps indoor spaces clean. These characteristics make it a valuable component in creating sustainable and eco-friendly building materials.

What is the role of diatomaceous earth in preventing diseases related to humidity and temperature conditions

Diatomaceous earth can help prevent diseases associated with humidity and temperature conditions by absorbing excess moisture and maintaining a dry environment. This can deter the growth of microorganisms and pathogens that thrive in damp conditions, helping to create a healthier and more disease-resistant environment.

How does diatomaceous earth serve as an effective deodorant, and in what applications is it commonly used for this purpose

Diatomaceous earth acts as a deodorant by absorbing and neutralizing odors. It is commonly used to remove unpleasant smells in various applications, including litter boxes, pet areas, and other spaces where odors need to be controlled. Its natural odor-fighting properties make it a popular choice for maintaining fresh and clean environments.

What are the common industrial applications of diatomaceous earth

Diatomaceous earth finds wide usage in various industries due to its unique properties. It serves as insulation materials, filter materials, fillers, grinding materials, raw materials for water glass, decolorizing agents, diatomite filter aids, and catalyst carriers. Additionally, it can be applied to industries like paint and paint additives after undergoing processing procedures like crushing, grinding, sorting, calcination, airflow classification, and impurity removal.

What are the different types of grinding mills available for processing diatomaceous earth, and how should one choose the most suitable one

There are different types of grinding mills available for processing diatomaceous earth, and the choice should be based on specific production needs. For those with a limited budget, HGM series ultrafine mills are a cost-effective option, offering stable operation, simple maintenance, and environmental friendliness. However, for industries with higher powder quality requirements, the CLUM series vertical mills are more suitable, providing a higher output and superior powder quality.

How is diatomaceous earth used in the agriculture industry

In agriculture, diatomaceous earth has several applications, depending on its particle size. Diatomaceous earth powder with various mesh sizes can be used as fillers, filter aids, and ingredients in the production of agricultural products such as wettable powder herbicides for dry land and paddy fields, as well as various biological pesticides. Different mesh sizes are suitable for different agricultural purposes.