What are some key considerations when selecting a grinding mill for marble powder production

When choosing a grinding mill for marble powder production, several factors should be considered:

- The desired fineness of the finished powder.

- The required output and production capacity.

- The space available in the production facility.

- The initial investment and operating costs.

- The expected service life of the mill.

- The specific requirements of the target industry and product quality.

Ultimately, the selection of the right mill should be based on a thorough evaluation of these factors to meet the specific needs of the production process.

What are the main applications of marble powder in the construction industry

Marble powder is widely used in the construction industry for various purposes. It can be employed in construction, interior and exterior wall coatings, chemical raw material filling, weighting, papermaking, sealants, and other chemical products. The fineness of the marble powder used in construction typically ranges from 80 to 200 mesh.

What is the Mohs hardness of marble, and how is it ground into powder

Marble has a Mohs hardness between 2.5 and 5. It can be ground into powder using an industrial powder mill, such as the SBM ultrafine powder grinding mill. This equipment is specifically designed to handle materials with various hardness levels and can produce marble powder of different fineness, ranging from 150 to 3000 mesh.

What are the common uses of marble powder in various industries

Marble powder finds applications in a variety of industries, including construction, chemical, coatings, and more. It is used as a filler in coatings, plastics, rubber, and other materials. The powder's fineness can vary, with common options being 200 meshes, 400 meshes, 600 meshes, 800 meshes, and more than 1250 meshes. These fineness options make it versatile and valuable in different applications within these industries.

How does the crushing process work for marble in the production of marble powder

The crushing process for marble in the production of marble powder involves using a crusher to break down large pieces of marble into smaller fragments. The crusher reduces the marble to a size that can meet the fineness requirements for the feed material of the ultrafine grinding mill. If the initial marble scrap is already within the required particle size range, there's no need for the crushing stage.

What are some specific uses of finer grades of marble powder, such as those above 800 mesh

Finer grades of marble powder, typically above 800 mesh, have various applications in different industries. It can be utilized in rubber, plastic, cable, PVC filler, and other fields. Additionally, it can be used as a raw material for high-end products like paints, coating products, inks, and more. The ultra-fine quality and high fineness of the powder make it suitable for these specialized applications.

What are the key stages in the production process of marble powder

The production process of marble powder involves several stages:

- Crushing Stage: Large pieces of marble are crushed until they meet the fineness requirements for the ultrafine grinding mill feed material.

- Grinding Stage: The ground marble is fed into the ultrafine mill, where it is finely ground into powder.

- Classification Stage: The ground marble powder is classified by a classifier, and unqualified powder is sent back for re-grinding.

- Powder Collection Stage: The fine powder is collected, separated from gas, and sent to a silo for packaging.

What are the potential environmental and economic benefits of using marble powder in various industries

The use of marble powder in various industries can have several environmental and economic benefits. It can help reduce waste by utilizing leftover marble materials. By incorporating marble powder into products, industries can enhance product properties and performance. Additionally, marble powder can be used as a co-solvent for various applications, including battery lead acid removers and soil neutralization. It can also act as a cement set-adjusting agent to improve the performance of cement concrete.

How is marble powder used as a raw material in plastics and rubber production

Marble powder serves as a raw material in plastics and rubber production. It is usually ground to a fineness of 250-300 mesh. In these industries, marble powder is used to enhance the properties of the final products, such as plastics, rubber, coatings, and waterproof materials, by acting as a filler.

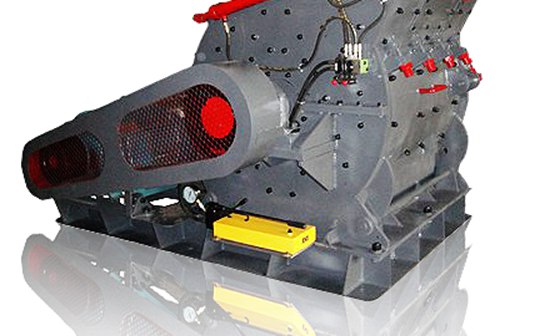

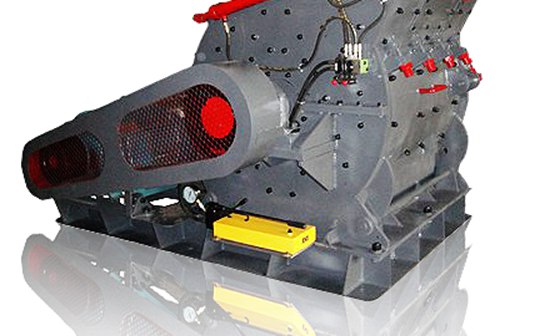

What are the primary machines used in marble mining and processing

Marble mining and processing involve several machines, including jaw crushers and impact crushers. These machines play a crucial role in breaking down and processing marble into various products. Jaw crushers use a curved extrusion method to crush material, while impact crushers work by repeatedly crushing the material until it reaches the desired particle size.

What types of grinding mills are suitable for processing marble powder, and how do they differ

There are various types of industrial grinding mills suitable for processing marble powder. Two main options include the HGM series ultrafine mills and the CLUM series superfine vertical mills. Both types can produce marble powder within the range of 150-3000 mesh. The choice between them depends on factors like the desired output, the properties of the finished powder, space constraints, initial investment, and more. The CLUM series is recommended for high-end, high-quality production.

What is the main component of marble powder, and how can it be repurposed in various industries

The main component of marble powder is calcium carbonate. This component can be repurposed in various industries, such as using it as a co-solvent for battery lead acid removers and for neutralizing acid soil. The by-products of marble powder can also serve as cement set-adjusting agents to enhance the performance of cement concrete. In summary, the versatile nature of marble powder allows it to find applications in different industries, contributing to environmental and economic benefits.